Tesla just released the Model 3 Performance on Tuesday, and already Tesla has hiked the price by $1,000.

Expand Expanding Close

Goodyear has debuted the ElectricDrive 2, a second-gen all-season EV tire – but are EV-specific tires worth putting on your electric vehicle?

Expand Expanding Close

The newly designed Hyundai Kona Electric is better in every way, with more range, faster charging, and a bold new style. Hyundai’s new 2024 Kona Electric is even cheaper to lease than the gas-powered model, starting at $169 per month.

Expand Expanding Close

On the Electrek Podcast, we discuss the most popular news in the world of sustainable transport and energy. In this week’s episode, we discuss all the news coming out of Tesla’s earnings, Model 3 Performance, Mercedes-Benz electric G-Class, and more.

Sponsored by SplitVolt: The Splitvolt Splitter Switch automatically shares power from your existing 240V dryer socket with your Level 2 EV charger. Learn more here.

Rivian has promised free NACS adapters will be sent out to its owners, and it’s starting that process now.

Expand Expanding Close

We’ve got another day of e-bike discounts on today’s Green Deals, headlined by Heybike’s Mother’s Day Sale that it taking up to $700 off a large selection of models, most notably the Explore Step-Thru Off-Road e-bike for $1,199. It is joined by another 1-day sale on the NIU BQi-C3 Pro e-bike that is back at its $1,300 low, as well as another returning low rate for the blue Hover-1 Altai Pro R500 e-bike at $954. Plus all of the other days’ Green Deals that are still going.

Head below for other New Green Deals we’ve found today and, of course, Electrek’s best EV buying and leasing deals. Also, check out the new Electrek Tesla Shop for the best deals on Tesla accessories.

Expand Expanding Close

Construction giant Skanska has been awarded a contract to turn the South Brooklyn Marine Terminal into one of the US’s largest offshore wind ports.

Expand Expanding Close

After Kia’s first three-row electric SUV is already seeing strong demand, the EV9 is set to gain a high-performance GT version. Kia confirmed the EV9 GT will launch in January with “enormous power” and other upgrades.

Expand Expanding Close

Mazda unveiled two new EVs, the EZ-6 electric sedan and the Arata SUV, at the Beijing Auto Show. Although Mazda’s new EVs are for China, they are what the brand is missing in the US.

Expand Expanding Close

Tesla Autopilot finds itself once again under NHTSA investigation after the agency is now doubting the effectiveness over the 2-million vehicle “recall” last year.

Expand Expanding Close

China’s BYD is unleashing a series of new electric vehicles as it expands the brand globally. BYD unveiled two new EVs at the Beijing Auto Show: a sleek Ocean-M electric hatch and the Denza Z9 GT EV. Check out the first images below.

Expand Expanding Close

Formula E unveiled its new “Gen3 EVO” car, an update to the Gen3 car which debuted last season, ahead of the Monaco ePrix this weekend.

Expand Expanding Close

Gogoro has been on a roll lately, showing off a steady stream of new scooter models and simultaneously expanding its markets into new countries. Now, the battery-swapping electric scooter leader is adding another pin to the map: Nepal.

Expand Expanding CloseListen to a recap of the top stories of the day from Electrek. Quick Charge is now available on Apple Podcasts, Spotify, TuneIn and our RSS feed for Overcast and other podcast players.

The first of 23 caissons for Princess Elisabeth Island, the world’s first artificial energy island, is nearly complete.

Expand Expanding Close

Honda is finally joining the EV race after announcing a massive $11 billion (CAD$15 billion) investment to build four new EV plants in Canada. The historic investment will be used to build Canada’s first EV supply chain, enabling 240,000 Honda EVs to be made for the US and Canada annually.

Expand Expanding Close

The Environmental Protection Agency (EPA) will require existing coal-fired and new natural gas-fired power plants to control 90% of their carbon emissions or shut down.

Expand Expanding Close

EV conversion specialist Everrati announced reshuffling its business-to-business (B2B) strategy, rebranding the division as “Powered by Everrati.” The branding partially results from increased customers to the B2B division, which is reporting encouraging year-over-year growth.

Expand Expanding Close

Following similar announcements from rivals, Hyundai is adding more hybrids to its lineup as a bridge to its next-gen EVs. Hyundai will add hybrid production lines at its dedicated EV plant in Georgia as demand rises.

Expand Expanding Close

The White House just debuted a plan to expand the grid’s capacity by upgrading 100,000 miles of transmission lines over the next five years.

Expand Expanding Close

We have have a truly summer-inspired lineup of Green Deals today, headlined by Rad Power’s latest flash sale that is taking up to $500 off four e-bike models, with the RadRover 6 Plus e-bike falling to a new $1,099 low. It is joined by the reappearance of the Rachio 3 3rd Generation Smart 4-Zone Sprinkler Controller that we haven’t seen discounted in a while, now at $99, as well as an even rarer 1-day sale on Anker’s EverFrost Dual-Zone Portable Cooler 50 for $619. Plus all of the other days’ Green Deals that are still going.

Head below for other New Green Deals we’ve found today and, of course, Electrek’s best EV buying and leasing deals. Also, check out the new Electrek Tesla Shop for the best deals on Tesla accessories.

Expand Expanding Close

XPeng Motors kept things relatively short but sweet during its 20-minute presentation at the 2024 Beijing International Auto Show earlier today, but there’s a lot to get excited about following several updates from XPeng founder, chairman, and CEO He Xiaopeng, including an “entirely new breed” of EVs under a new sub-brand. Here’s the full recap.

Expand Expanding Close

Another fully electric large Toyota SUV is on its way. Toyota announced it’s preparing its three-row electric SUV as part of a new $1.4 billion investment in Indiana. Is this the electric Toyota Highlander EV we’ve been waiting for?

Expand Expanding Close

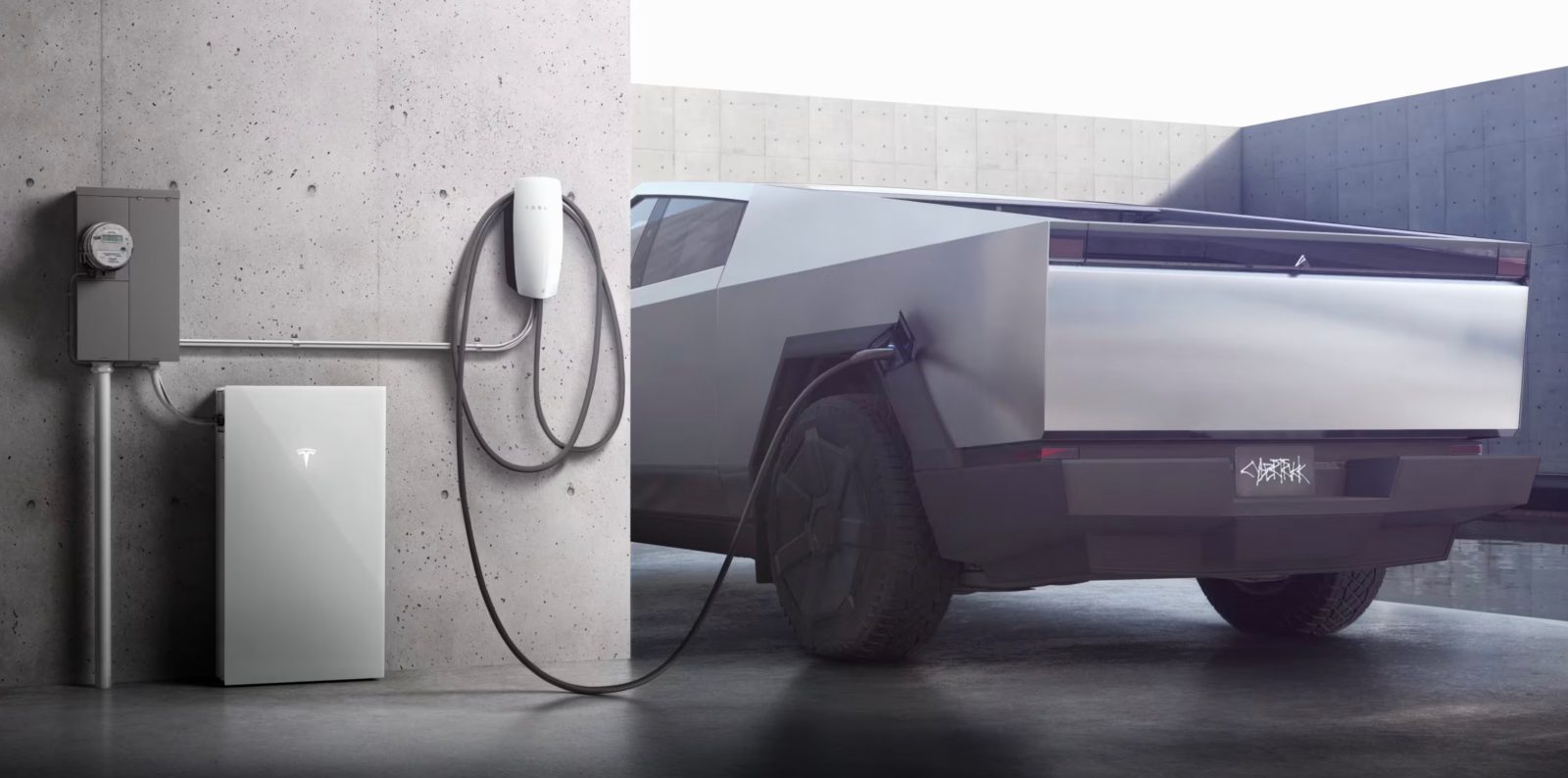

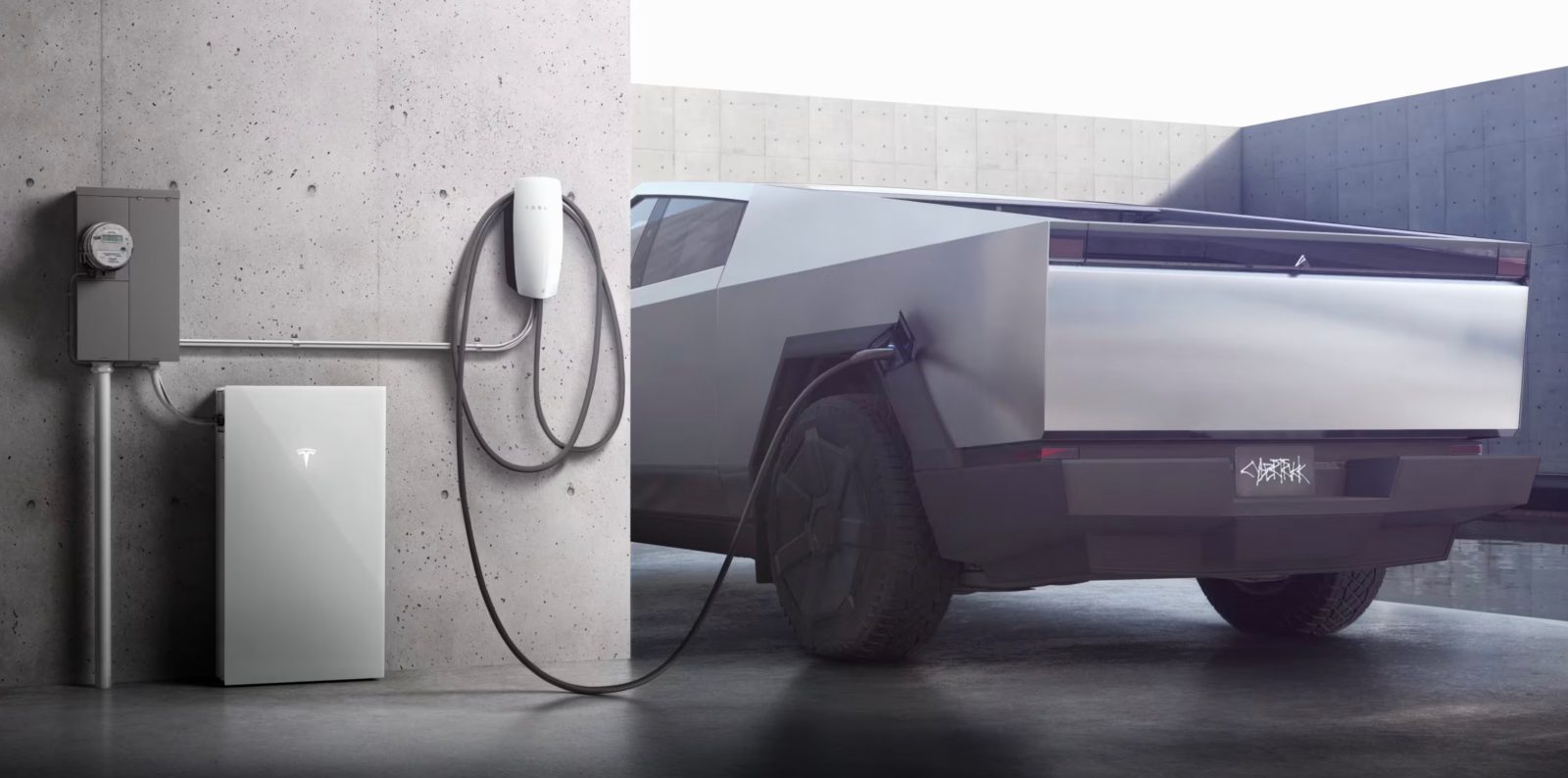

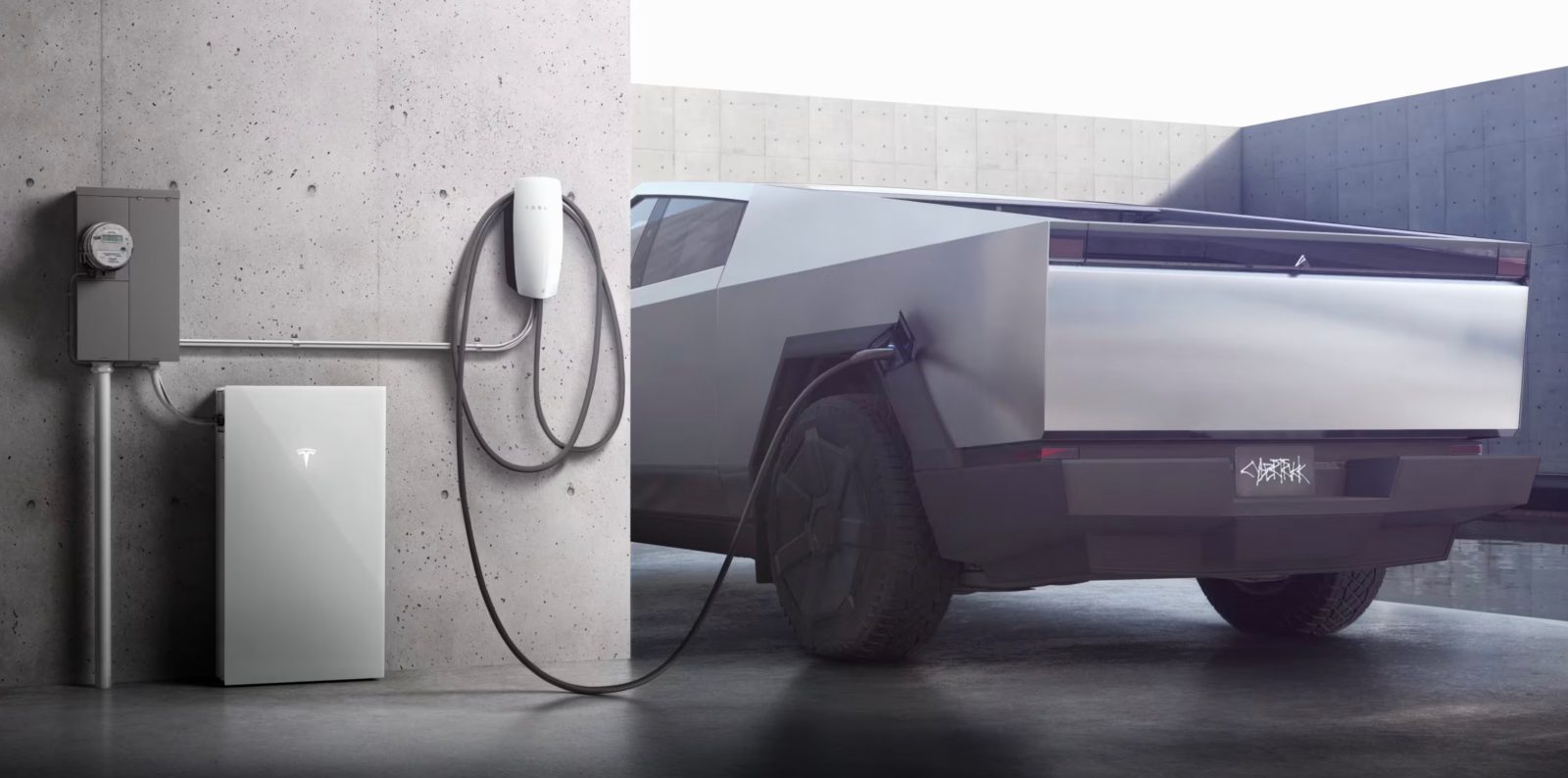

A Tesla Cybertruck owner has been quoted over $30,000 for a Powershare installation to enable his electric pickup truck to power his house.

Expand Expanding Close