North America just got a new recycled Li-ion battery materials plant

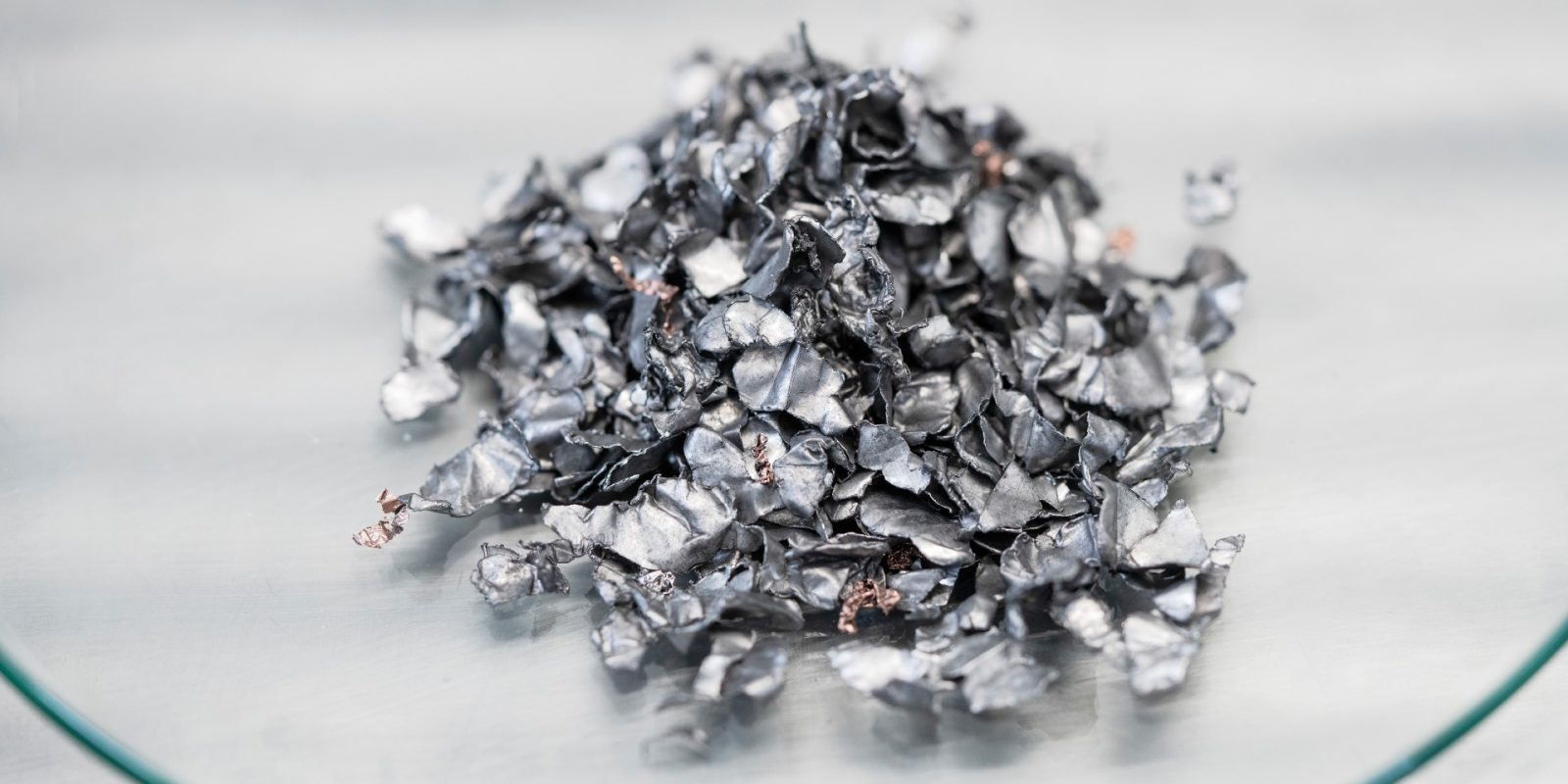

Green Li-ion has launched a commercial-scale plant to process unsorted battery waste, or “black mass,” from used lithium-ion batteries.

Expand Expanding Close

Green Li-ion has launched a commercial-scale plant to process unsorted battery waste, or “black mass,” from used lithium-ion batteries.

Expand Expanding Close

Great news for EVs: Lithium Nevada got the green light for a $2.26 billion loan from the US Department of Energy to finance a lithium carbonate processing plant.

Expand Expanding Close

In a significant advancement for EV technology, researchers at Chung-Ang University in South Korea have made a breakthrough in lithium-ion (Li-ion) battery charging times and safety.

Expand Expanding Close

A plan has been hatched to expand and diversify critical mineral supply chains globally for the booming EV battery industry – will it work?

Expand Expanding Close

A New Zealand-based startup just got $18 million to commercialize graphite made of wood chips for EV batteries in Europe and the US.

Expand Expanding Close

Four companies will together produce new lithium-ion EV batteries that contain recycled metals in a US first.

Expand Expanding Close

Scientists at Edith Cowan University in Australia found that zinc-air batteries could be a better alternative than lithium-ion batteries to power EVs.

Expand Expanding Close

Amprius Technologies (NYSE: AMPX) today announced that its high-energy, high-power lithium-ion battery with a silicon anode platform has been verified by an independent test lab.

Expand Expanding Close

Battery recycling giant Ecobat is building its first lithium-ion battery recycling facility in North America – its third li-ion battery recycling facility globally.

Expand Expanding Close

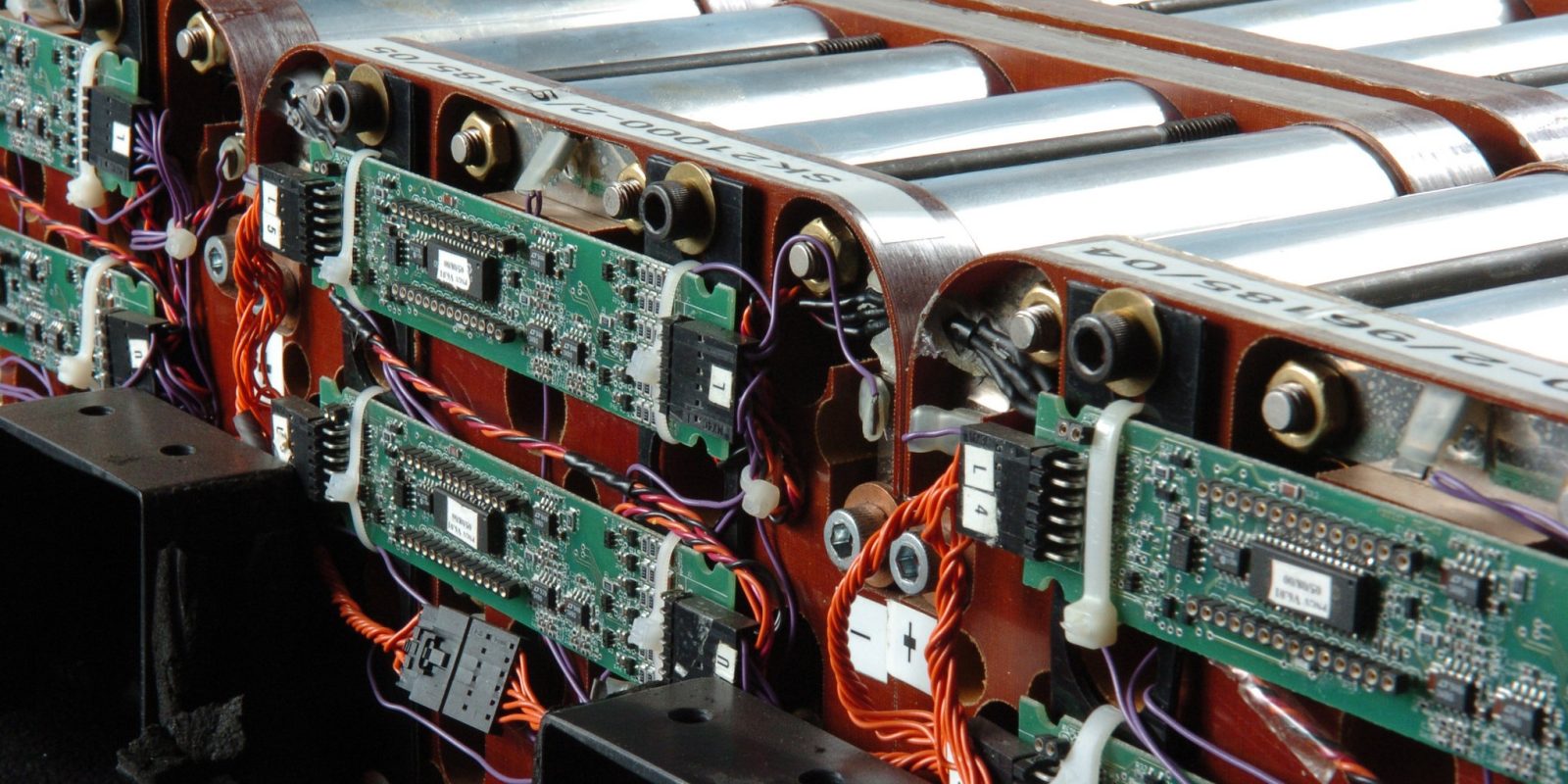

NanoGraf Technologies, which claims it has enabled the highest energy-density cylindrical 18650 Lithium-ion cell in the world, has raised $65 million in an oversubscribed Series B funding round. 18650 cells are used in the production of electric vehicles.

Expand Expanding Close

In order to qualify for the $7,500 tax credit, the Biden administration’s Inflation Reduction Act (IRA) requires a proportion of battery minerals in EVs to be extracted or processed in the US or free-trade partner countries. But a lot of automakers simply aren’t prepared for that requirement.

Electrek spoke with Megan O’Connor, cofounder and CEO of Nth Cycle, a Beverly, Massachusetts-based metals processing tech company, about how her company can help EV manufacturers address this challenge quickly.

Expand Expanding Close

In March, electric vehicle battery startup StoreDot said it would produce battery cells that will be able to achieve a charge of 100 miles of range in just five minutes. The Israel-based company has delivered: It’s now shipping production-ready “100in5” EV cell samples to its strategic EV OEM partners and potential customers.

Expand Expanding Close

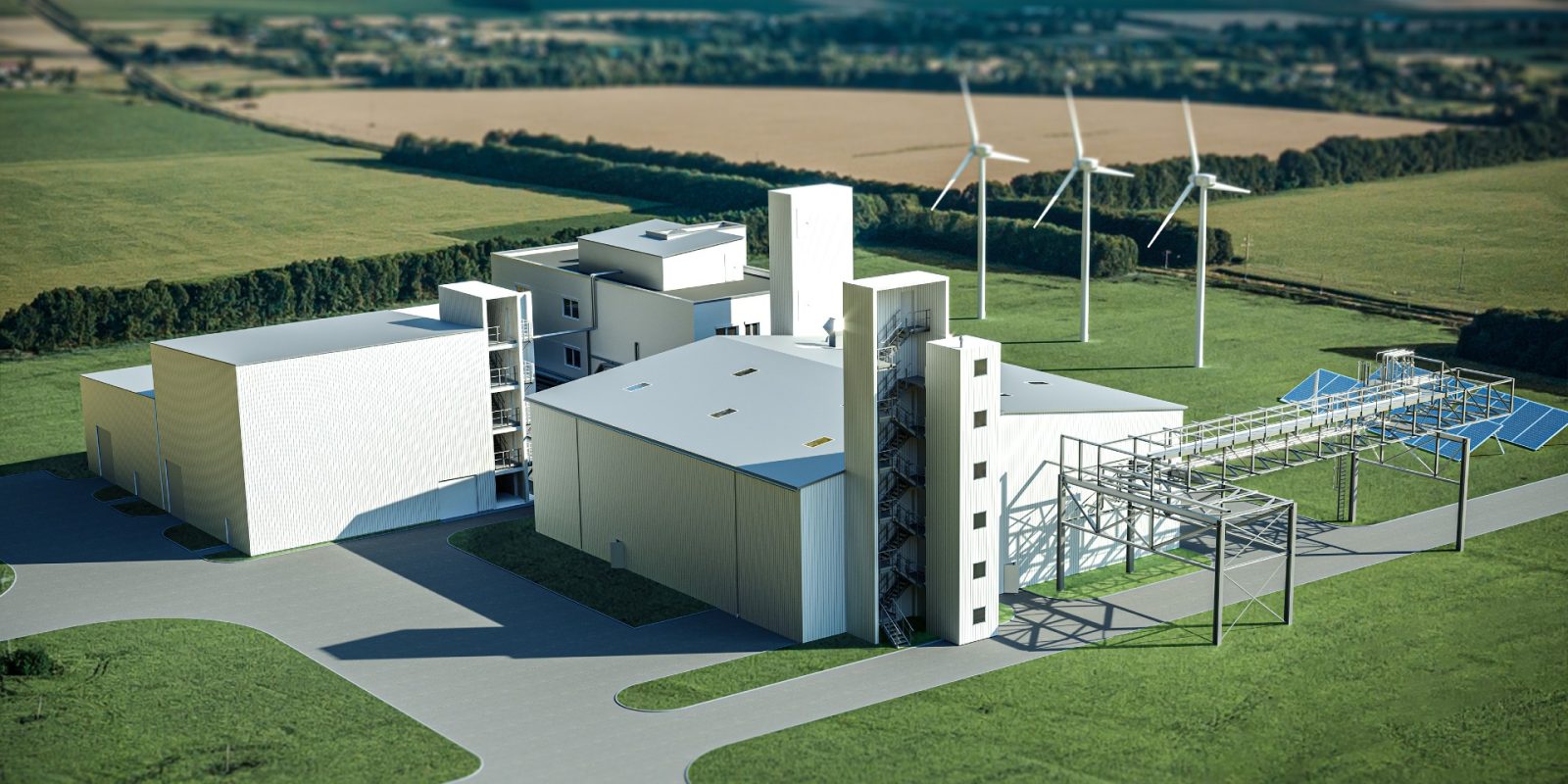

Global chemical giant BASF is going to build a commercial battery-recycling, black-mass plant in Schwarzheide, a town in Brandenburg, eastern Germany.

Expand Expanding Close

Automakers are racing to produce electric vehicles, yet few firms currently know how to recycle old EV batteries. Experts at the Argonne National Laboratory, a US Department of Energy science and engineering research center in Lemont, Illinois, are inviting the public to listen in as experts explore the challenges – and solutions – of recycling lithium-ion batteries.

Expand Expanding Close

The mineral graphite, as an anode material, is a crucial part of a lithium-ion (Li-on) battery. Electrek spoke with John DeMaio, president of the Graphene Division of Graphex Group and CEO of Graphex Technologies. Read on to learn what he had to say about why graphite’s so important for EVs, what his company is doing to ramp up US sourcing and processing, and what the graphite supply is expected to be in the next couple years.

Expand Expanding Close

StoreDot, an Israel-based electric vehicle extreme fast charging (XFC) battery startup, today announced that it has advanced technology that extends the life span of batteries, making them highly effective not only during the vehicle life span, but also for second-life applications.

Expand Expanding Close

As the electric car revolution ramps up, so does the need for critical minerals used in batteries, such as graphite. According to Benchmark Mineral Intelligence, there will be a global graphite deficit starting in 2022, and demand from the battery sector is expected to rise 30% annually until 2030. The US has no manufacturing plants that can supply automotive-grade graphite at scale. Meanwhile, China controls 84% of the global supply. Electrek spoke with Don Baxter, CEO of Ceylon Graphite, about how graphite is used in EVs, the supply chain issue, and how EV battery manufacturers can successfully source the vital mineral.

Expand Expanding Close

Researchers have developed a prototype lithium-ion battery that uses water as an electrolytic solution. The water replaces a flammable organic solvent.

Expand Expanding Close

StoreDot, an Israel-based electric vehicle battery startup, yesterday announced new patented technology that uses a background repair mechanism to allow battery cells to regenerate while they are in use. The company says the new technology will result in longer battery life and better EV performance.

Expand Expanding Close

More than 1 million electric vehicles are now driving on US roads. What will happen when those cars go out of service? The plan is to recycle their batteries.

Expand Expanding Close

StoreDot, an Israel-based electric vehicle battery startup, today claimed that it has become the first company to produce silicon-dominant extreme fast charge (XFC) cells for electric vehicles on a mass production line.

Expand Expanding Close

Lithium-ion battery development and production is rapidly escalating worldwide, yet there’s no standard when it comes to battery designs, materials, and chemistries. And that affects the ability to recycle Li-ion batteries – a vital final stage of their life cycle. But this may be about to change in the US.

Expand Expanding Close

Zambian president-elect Hakainde Hichilema won a landslide victory in the country’s election last week, beating the incumbent, Edgar Lungu. Hichilema’s plan is to ramp up mining in particular to jump-start Zambia’s economy – and provide the rapidly growing electric vehicle battery industry with crucial cobalt and copper.

Expand Expanding Close

This video tells the story of cobalt and its importance to batteries and electric cars.

Expand Expanding Close