[youtube=https://www.youtube.com/watch?v=bsAy7FMhozY&feature=youtu.be]

Nissan celebrates 100,000 LEAFs and miles on one car

Founder, Publisher, and Editorial Director of the 925, LLC publications.

Seth Weintraub is an award-winning engineer, journalist, and publisher who won back-to-back Neal Awards from 2007–2010 during his three-plus years covering Apple and Google at IDG’s Computerworld.

From 2010-2011, Weintraub covered all things Google for Fortune Magazine, amassing an impressive rolodex of Google contacts and a love for Silicon Valley tech culture.

It turns out that his hobby – the 9to5Mac news site – was always his favorite, and in 2011, he went full time adding his Fortune Google followers to 9to5Google, in addition to adding the style and commerce component of 9to5Toys gear and deals site. In 2013, Weintraub bought one of Tesla’s first Model S EVs off of the assembly line, which began his love affair with electric vehicles and green energy — this, in turn, became Electrek in 2014. To cover the burgeoning world of drones and UAVs led by China’s DJI, DroneDJ was born in 2018, and then more recently, Connectthewatts and SpaceExplored were launched to cover connected fitness and space.

From 1997-2007, Weintraub was a Global IT director and Web Developer for a number of companies, with stints at multimedia and branding agencies in Paris, Los Angeles, New York, Sydney, Hong Kong, Madrid, and London before becoming a publisher/writer.

Seth received a bachelor’s degree in Industrial and Systems Engineering from the University of Southern California with a minor in Multimedia and Creative Technology in 1997. In 2004, he received a Master’s from NYU’s Tisch School of the Art’s ITP program.

Weintraub is a licensed single-engine private pilot and a certified open-water scuba diver, and he spent over a year backpacking to 60 cities in 23 countries. Whatever free time exists is now guaranteed to his wonderful girlfriend, Alana, and two amazing sons.

More: About.me. BI 2014 profile.

Tips: seth@925.co, or llsethj on Threads/BlueSky or link at top of page.

[youtube=https://www.youtube.com/watch?v=bsAy7FMhozY&feature=youtu.be]

I like this idea a lot.

Interesting move. Juniper makes large scale networking equipment that runs on the backbone of the Internet and at ISPs as well as larger corporations. Denholm began her career in Australia serving at Toyota Motor Corporation for seven years and at Arthur Andersen and Company for five years in various finance assignments.

Interesting move. Juniper makes large scale networking equipment that runs on the backbone of the Internet and at ISPs as well as larger corporations. Denholm began her career in Australia serving at Toyota Motor Corporation for seven years and at Arthur Andersen and Company for five years in various finance assignments.

PALO ALTO, CA, August 6, 2014 – Tesla today announced that Robyn Denholm, Executive Vice President, Chief Financial and Operations Officer at Juniper Networks, Inc., has been appointed to its board of directors, effective August 11, 2014.

Denholm has also been appointed to chair the company’s Audit Committee and be a member of the Compensation and Nominating and Corporate Governance committees. These roles were previously filled by Brad Buss, who is vacating his committee positions upon joining SolarCity as its Chief Financial Officer. Buss will remain a member of Tesla’s board and will provide valuable continuity from his experience since joining the board in 2009.

Denholm joined Juniper in 2007 and has helped the company achieve record revenues while delivering breakthrough innovations to customers. In 2011, Denholm was a Bay Area CFO of the Year finalist and she was recently named on Silicon Valley Business Journal’s Women of Influence List. She joined Juniper from Sun Microsystems, where she served as Senior Vice President, Corporate Strategic Planning.

Denholm began her career in Australia, serving in various finance assignments for Toyota Motor Corporation and Arthur Andersen and Company. She holds a bachelor’s degree in economics from the University of Sydney and a master’s degree in commerce from the University of New South Wales. At Juniper, she is responsible for company’s finance, administration and business operations, including planning, IT, real estate, investor relations, internal audit, and manufacturing operations.

Media Contact:

Tesla Motors

press@teslamotors.com

Tel: +1650-833 8456

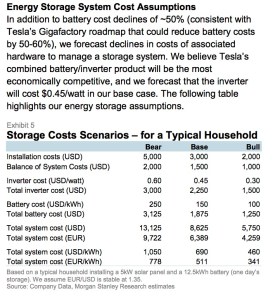

The analysts at Morgan Stanley (PDF) think that Tesla and solar utilities like Solar City could join forces to create energy products that would allow Americans to drop off their energy carrier’s grid delivery system. The price of storage of electricity and solar will soon cost less than hooking homes up to the grid and Americans and Europeans will start dropping off not just to be green but also to save money.

The analysts at Morgan Stanley (PDF) think that Tesla and solar utilities like Solar City could join forces to create energy products that would allow Americans to drop off their energy carrier’s grid delivery system. The price of storage of electricity and solar will soon cost less than hooking homes up to the grid and Americans and Europeans will start dropping off not just to be green but also to save money.

Energy storage, when combined with solar power, could disrupt utilities in the US and Europe to the extent customers move to an off-grid approach. We believe Tesla’s energy storage product will be economically viable in parts of the US and Europe, and at a fraction of the cost of current storage alternatives.

Energy storage, specifically Tesla’s product, could be

disruptive in the US and Europe, but is less likely to be

economic in the rest of the world. Given the relatively high

cost of the power grid, we think that customers in parts of the

US and Europe may seek to avoid utility grid fees by going

“off-grid” through a combination of solar power and energy

storage. We believe there is not sufficient appreciation of the

magnitude of energy storage cost reduction that Tesla has

already achieved, nor of the further cost reduction magnitude

that Tesla might be able to achieve once the company has

constructed its “Gigafactory,” targeted for completion later in

the decade. While “off-grid” applications are the most

disruptive use of energy storage, we note that there are also

less disruptive applications such as strengthening the grid to

compensate for the variability of solar output.

Even at the Base/Bear cost of $10,000 for 25+ years of power, it seems like a no brainer for most households. With solar companies already financing the upfront costs, it would seem like cost reductions against a increasing grid market will flip the switch soon. Add in the cost of auto fuel savings when using electric cars and it is even more enticing.

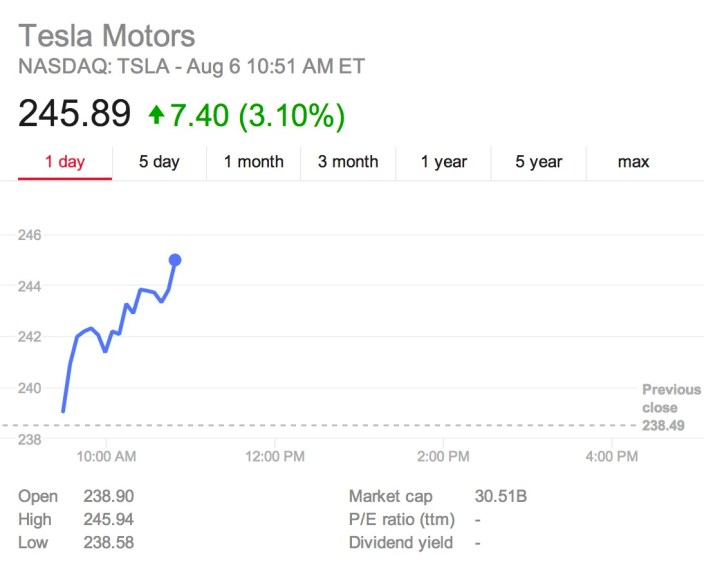

TSLA shares are up today in early trading.

It looks like Tesla is indeed breaking ground on a Gigafactory site near Reno if this image/story from Bob Tregilus is true:

Yesterday, our unnamed source (Bob Tregilus) hiked a few high-desert ridges in Storey County, Nevada to take pictures of 50 earthmovers moving earth at a site that Tregilus estimated to be large enough to accommodate the proposed 10-million-square-foot factory. Tregilus has also heard whispers about a secret project from construction industry folks and locals.

The site is located at the Reno Tahoe Industrial Center at 2641 Portofino Drive.

[youtube=https://www.youtube.com/watch?v=9N4gAKdKr4o&feature=share]

But does the Lamborghini seat 7 with a frunk?

With a price tag close to $300,000, this Lamborghini is named after the Super Trofeo Racing Series and is equipped and modeled after the Lamborghini race cars. The STS is Lamborghini’s lightest Gallardo at just 3,400 pounds (real world weight) and is powered by a 5.2L V10 making 570 horsepower through a 6 speed e-gear automated transmission with all wheel drive. We tested the STS earlier in the year and ran 11.2 @ 126.5 MPHwhich was the quickest time for any Gallardo down the drag strip.

The $95,000 Tesla Model S P 85 is powered by an electric motor that is about the size of a small office trash can and makes 415 horsepower. With no transmission and a weight of 4,700 pounds, we tested this Model S earlier this year as well running a 12.3 @ 110.8 MPH.

Read more:Via Dragtimes

Nissan Motor and Mitsubishi Motors will work together to develop a minicar-based electric vehicle, aiming to release a new model in fiscal 2016 at the lowest price among major automakers. The carmakers have set up a 50-50 joint venture to pursue development. Nissan, which released the Leaf electric car in 2010, is the world’s largest manufacturer of electric vehicles, with global sales of at least 124,000 units. Mitsubishi has a track record in this area as well, including the minicar-based i-MiEV released in 2009. They plan to co-produce the new car and work together to procure such key components as lithium-ion batteries. The i-MiEV is the cheapest electric passenger car on the Japanese market, starting at 2.52 million yen ($24,300). When government subsidies of up to 740,000 yen are included, it can be purchased for as little as 1.78 million yen.

This will be interesting if they can build a car as good as a Leaf for as little or less than a i-MiEV. If they can do this, the math is almost unstoppable especially a gas prices rise.

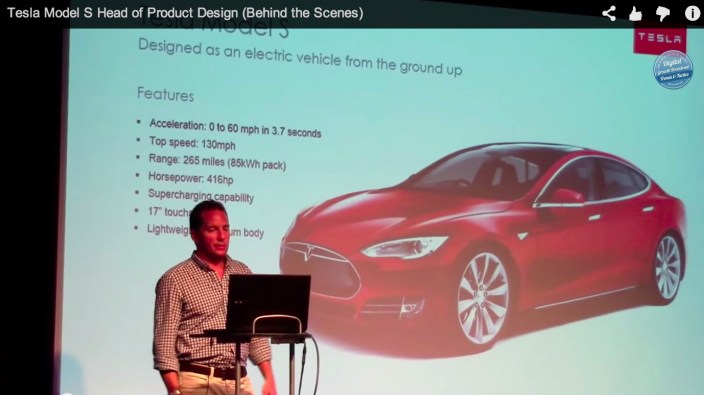

Update: Tesla tells us that the slide in question was an error, likely a leftover from the Roadster spec sheet.

I noticed an interesting slide in Tesla’s Director of Product Design and Project Management Javier Verdura‘s recent presentation (Above). Everything up there jibes with Tesla’s original Model S specs which can be seen on its front page (and below) except the 0-60 has moved from 4.2 seconds to 3.7 seconds. That’s a full half second faster and pushing the Model S way into Supercar territory. How did it get so much faster?

At first glance, I wasn’t sure if this wasn’t a misprint or a preliminary speed test from a 4-wheel drive version (also would be cool!). It is hard to imagine how Tesla could get from 4.2 to 3.7 seconds with the same car. However something said in the conference call yesterday might explain the extra speed, or at least some of it. The question was from Northland Capital Markets’ Colin Rush:

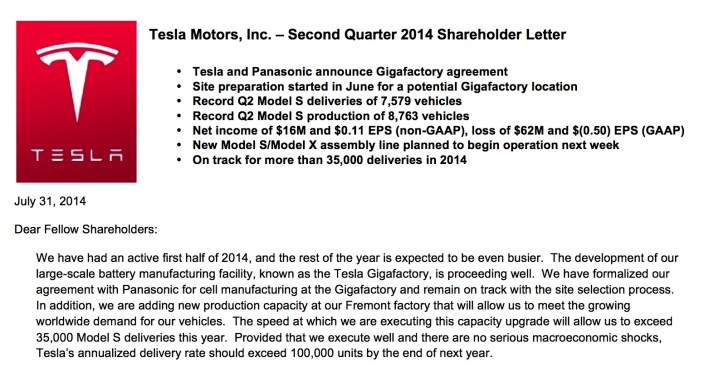

From today’s Shareholder Report(PDF):

In June, we broke ground just outside Reno, Nevada on a site that could potentially be the location for the Gigafactory. Consistent with our strategy to identify and break ground on multiple sites, we continue to evaluate other locations in Arizona, California, New Mexico and Texas. The final site for the first Gigafactory will be determined in the next few months, once we have full visibility and agreement on the relevant incentives and processes for enabling the Gigafactory to be fully operational to meet the timing for Model 3. We see these concurrent efforts as prudent. This vehicle will be

our third-generation product and will substantially broaden the addressable market for Tesla, helping to accelerate the transition towards sustainable transportation. Any potentially duplicative investments are minor compared to the revenue that could be lost if the launch of Model 3 were affected by any delays at our primary Gigafactory site.

Conference call will be at 5:30 here. Stock is down in after hours on unit shipment numbers.

PANASONIC AND TESLA SIGN AGREEMENT FOR THE GIGAFACTORY

THURSDAY, JULY 31, 2014

OSAKA, Japan / PALO ALTO, USA, July 31, 2014 – Panasonic Corporation and Tesla Motors, Inc. have signed an agreement that lays out their cooperation on the construction of a large-scale battery manufacturing plant in the United States, known as the Gigafactory.

According to the agreement, Tesla will prepare, provide and manage the land, buildings and utilities. Panasonic will manufacture and supply cylindrical lithium-ion cells and invest in the associated equipment, machinery, and other manufacturing tools based on their mutual approval. A network of supplier partners is planned to produce the required precursor materials. Tesla will take the cells and other components to assemble battery modules and packs. To meet the projected demand for cells, Tesla will continue to purchase battery cells produced in Panasonic’s factories in Japan. Tesla and Panasonic will continue to discuss the details of implementation including sales, operations and investment.

The Gigafactory is being created to enable a continuous reduction in the cost of long range battery packs in parallel with manufacturing at the volumes required to enable Tesla to meet its goal of advancing mass market electric vehicles. The Gigafactory will be managed by Tesla with Panasonic joining as the principle partner responsible for lithium-ion battery cells and occupying approximately half of the planned manufacturing space; key suppliers combined with Tesla’s module and pack assembly will comprise the other half of this fully integrated industrial complex.

JB Straubel, Chief Technical Officer and Co-founder of Tesla Motors said: “the Gigafactory represents a fundamental change in the way large scale battery production can be realized. Not only does the Gigafactory enable capacity needed for the Model 3 but it sets the path for a dramatic reduction in the cost of energy storage across a broad range of applications.”

Yoshihiko Yamada, Executive Vice President of Panasonic, added, “We have already engaged in various collaborative projects with Tesla toward the popularization of electric vehicles. Panasonic’s lithium-ion battery cells combine the required features for electric vehicles such as high capacity, durability and cost performance. And I believe that once we are able to manufacture lithium-ion battery cells at the Gigafactory, we will be able to accelerate the expansion of the electric vehicle market.”

Cost reductions will be achieved through optimized manufacturing processes driven by economies of scale previously unobtainable in battery cell and pack production. Further price reductions are achieved by manufacturing cells that have been optimized for electric vehicle design, both in size and function, by co-locating suppliers on-site to eliminate packaging, transportation & duty costs and inventory carrying costs, and by manufacturing at a location with lower utility and operating expenses.

The Gigafactory will produce cells, modules and packs for Tesla’s electric vehicles and for the stationary storage market. The Gigafactory is planned to produce 35GWh of cells and 50GWh of packs per year by 2020. Tesla projects that the Gigafactory will employ about 6,500 people by 2020.

Panasonic

http://panasonic.net/

Tesla Motors

http://www.teslamotors.com/blog-and-press-releases

Media Contacts:

Panasonic Corporation

Tel: +81-(0)3-3574-5664

Fax: +81-(0)3-3574-5699

Tesla Motors

press@teslamotors.com

Tel: +1650-833 8456

Except probably with more Tesla/chargers. Via

OSAKA — Panasonic has reached a basic agreement with Tesla Motors to participate in the Gigafactory, the huge battery plant that the American electric vehicle manufacturer plans to build in the U.S. Tesla aims to begin the first phase of construction this fiscal year. The plant would start making lithium-ion cells for Tesla cars in 2017. The automaker is shouldering the cost for the land and buildings. Panasonic likely will invest 20 billion to 30 billion yen ($194-291 million) initially, taking responsibility for equipping the factory with the machinery to make the battery cells. An official announcement on the partnership will come by the end of this month. Capacity at the Gigafactory will be added in stages to match demand, with the goal of producing enough battery cells in 2020 to equip 500,000 electric vehicles a year. The total investment is expected to reach up to $5 billion, and Panasonic’s share could reach $1 billion. The Japanese company owns a stake in Tesla and currently makes the batteries for Tesla cars. In a contract reworked in October 2013, the two agreed that Panasonic would supply Tesla with 2 billion battery cells between 2014 and 2017.

No breaking news here but a nice look behind the curtain of design at Tesla motors. Stick around for the Q&A at the end.

Join the second installment of RKS Sessions with Javier Verdura, Director of Product Design and Project Management for Tesla Motors. Verdura will give us a look under the hood of the innovative company- sharing their history, design process and where they’re headed in the future.

The second event in the series, RKS Sessions brings together luminaries and ideas focused on cutting edge user-experience, brand, service and product design. A monthly design-centric event series, it is jointly produced by RKS and Cross Campus. RKS Sessions is also a forum for the design community to share their ideas.

About Javier Verdura

Mexico City-born Javier Verdura graduated from Art Center College of Design with a BS in Product Design in 1991. In 1998 he joined the then start-up firm Product Ventures, he remained there for 15 years as the Vice President of Design and Development, during his tenure he helped grow the company from 6 employees to almost 50. His most recent position has brought Javier back to Los Angeles where he is currently the Director of Product Design at Tesla Motors. Over his 22-year career, Javier has designed everything from surgical equipment to consumer products and packaging. He has been recognized by winning some of the industry’s most prestigious awards: 3-time Red Dot winner, Multiple Good Design Awards (7) and an IDEA award. In addition, his name appears in more than 130 patents in US and abroad. Javier’s philosophy on Industrial Design: if you can’t manufacture what you create, it is not worth designing.

At Hong Kong’s Kai Tak Cruise Terminal earlier this week, Tesla handed eight owners the keys to the first right hand drive Model S’s in Asia. Jerome Guillen, Tesla’s Vice President of Worldwide Sales and Service, also unveiled Hong Kong’s first Superchargers, which allow Model S drivers to charge for free.

Edmunds documented their unofficial record-breaking “reverse Cannonball Run.”

“The key to breaking the record wasn’t to drive fast; we had to drive smart,” said Dan Edmunds. “Fast, aggressive driving will only succeed in sucking down an EV’s battery. We had to drive responsibly to make sure we had enough juice to get from one charging station to the next. And we saved time by charging only a little more than what we figured was necessary to get to the next Supercharger.”

The Trip Stats

After arriving in New York, the team headed back to California at a more leisurely 6 day pace.

[youtube=https://www.youtube.com/watch?v=RqLpqR0SPnQ]

The Quant looks like an amazing vehicle that has a 600km range and insane sub 3 second 4wd acceleration. A couple of things to keep in mind though:

1. If you have $1M to spend you could build a pretty big/fast Nissan Leaf or Tesla Model S.

2. Not much has been said about the nanoFlowCell and it is hard to gauge exactly how much storage it can produce

3. I hope my pessimism is wrong and they build lots of these.

Time to start making some Model Xes.

Tesla Motors shut down its production line Monday as part of a long-scheduled plan to retool the factory to increase production of the Model S sedan and prepare for the introduction of the Model X crossover SUV. “We’ll be back at regular production Aug. 4,” Simon Sproule, Tesla’s vice president of communications, said in an interview. “We’ll be down for 128 hours of regularly scheduled production time.” The new production line, which will cost roughly $100 million, is on the ground floor of the factory off Interstate 880 and will be used for both the Model S and forthcoming Model X. “It improves the overall flow for the plant,” Sproule said. “We’re installing new lines, reconfiguring the plant and making more use of the available space in Fremont.”

Interesting we still don’t know what the final product will look like. CEO Elon Musk noted at the recent shareholder conference that the design had changed significantly for the better since the latest prototypes had been displayed.

Qihoo 360 Technology Co. has found ways to remotely control the Tesla car’s locks, horn, headlights and skylight while the car is in motion, the Beijing-based Internet security company said in a posting on its Sina Weibo account. Wu Jing, a director of investor relations for the company, said its information technology department conducted the experiment, without elaborating.

These are all things you can control via the smartphone app while the car is in motion (fun trick to play on wife is cracking sunroof during rain) and maybe Tesla needs to rethink which of these things should be happening in motion.

So, it would appear that the hackers would be attacking the Brew API that the apps and third party apps use. That’s not terribly serious but obviously should be watched…as Tesla plans to do…

“While Tesla is not associated with the conference and is not a sponsor of the competition, we support the idea of providing an environment in which responsible security researchers can help identify potential vulnerabilities,” Palo Alto, California-based Tesla said in an e-mail. “We hope that the security researchers will act responsibly and in good faith.”

https://www.youtube.com/watch?v=U2qtmKKt9-U

B-Roll of the E-Fan Electric Airplane Flying. Provided for press use by Airbus from official press source. If you think this is cool, Airbus is working on a 90-seat regional based on the electric technology. More here and here

From Wiki:

Airbus Group is developing an electric aircraft with Aero Composite Saintonge. The aircraft uses on-board lithium batteries to power the two electric engines and can carry two passengers. A test flight was conducted in April 2014 at Mérignac Airport, France, landing in front of a large audience, the French Minister of Industry Arnaud Montebourg being one of them. At the 2014 Farnborough Airshow, Airbus announced that the E-Fan 2.0 will go into production by 2017 with a side-by-side seating layout.[1] Airbus has stated that there are plans for development of a commercial regional aircraft in the near future.[2][3]

The E-Fan is an all-electric two-seat twin-engined low-wing monoplane of composite structure. It has a T-tail and a retractable tandem landing gear with outrigger wheels. The two engines are mounted either side of the rear fuselage.

Two production variants are planned, a two-seater E-Fan 2.0 for use as a trainer, and the E-Fan 4.0 four-seater. To increase the duration the E-Fan 4.0 will have a hybrid-electric system that will have a small engine to charge the battery, this will increase duration from nearly an hour to 3.5 hours.[4]

The E-fan is made of an all-composite construction propelled by two ducted, variable pitch fans spun by two electric motors totaling 60 kW of power. Ducting increases thrust while reducing noise, and having the fans mounted centrally provides better control. The motors moving the fans are powered by a series of 250 Volt lithium-ion polymer batteries made by South Korean company Kokam. The batteries are mounted in the inboard section of the wings and have enough power for one hour, and take one hour to recharge; an onboard backup battery is available to make an emergency landing if power runs out while airborne. The E-fan’s undercarriage consists of two retractable fore and aft wheels, with another two under the wings. They are powered by a 6 kW electric motor that not only taxis the plane, but is capable of accelerating it to 60 km/h (37 mph; 32 kn) for take offs; having the take off performed by the undercarriage relieves some of the burden from the flight motors.[5]

PALO ALTO, Calif., July 17, 2014 – Tesla announces that it will post its financial results for the second quarter ended June 30, 2014, after market close on Thursday, July 31, 2014. At that time, Tesla will issue a brief advisory release containing a link to the Q2 2014 Shareholder Letter, available on the company website. Tesla management will hold a live question & answer webcast at 2:30pm Pacific Daylight Time (5:30pm Eastern Daylight Time) to discuss the Company’s financial and business results and outlook.

What: Tesla Motors, Inc. Q2 2014 Financial Results Q&A Webcast

When: Thursday, July 31, 2014

Time: 2:30pm Pacific Daylight Time / 5:30pm Eastern Daylight Time

Shareholder Letter: http://ir.teslamotors.com

Webcast: http://ir.teslamotors.com (live and replay)

Approximately two hours after the Q&A session, an archived version of the webcast will be available on the Company’s website for a period of one year.

Investor Relations Contact:

Jeff Evanson

Tesla Motors

ir@teslamotors.com

Press Contact:

Simon Sproule

Tesla Motors

press@teslamotors.com

For additional information, please visit ir.teslamotors.com.

Mr. Zong lives in the southern Chinese boomtown of Guangzhou, where he founded a business that makes energy-efficient equipment like water heaters for swimming pools. In April, Tesla Motors Inc. delivered its first cars to customers in China in Beijing, about 1,300 miles to the north. Tesla doesn’t operate enough charging facilities between the cities to allow him to drive his car home.

Undaunted, Mr. Zong decided to build his own charging network. With the help of partners found online, he bought 20 charging pillars from Tesla for 5,000 yuan (about $800) each and put them in 16 cities along the way.

“I thought it would be cool if I could build China’s first electric-car-charging road,” said Mr. Zong, who completed the installations last month. A Tesla spokeswoman said the company is aware of, and approves of, Mr. Zong’s ambitions.

[youtube=https://www.youtube.com/watch?v=u7xfuuHNO_g]

Menga and his client collected $126,836 in the lawsuit. This includes the cost for the company to buy the car back, all the accessories for the car and $18,500 in attorney fees

It’s unfortunate but settling for a relatively small amount is a lot easier than giving this guy a courtroom platform, though it does set a worrisome precedent and this guy clearly is trying to use his 15 minutes of fame to get more business. Asshat.