Tesla has applied to build a giant new facility, seemingly to produce cathode materials for battery manufacturing, next to “Gigafactory Texas” in Austin.

In 2020, Electrek first revealed that Tesla is going to build its next Gigafactory in Austin. Later, it was confirmed that Tesla acquired over 2,000 acres of land around the Colorado River east of the city. Two years later, Tesla has now built a giant building for the main factory at what is now called “Gigafactory Texas”.

Last month, it was confirmed that production of the Model Y has started at the new factory, and the automaker also deployed part of a battery cell production in the building. But with over 2,000 acres, Tesla has been expected to deploy several new projects around the main factory.

Last year, it was revealed that Tesla was working on a new “Project Bobcat” on around 97 acres at the site. Now, Tesla has applied for another project, codename ‘Project Cathode’, on 32 acres at the site.

In the building application obtained by Electrek (hat tip to Vinod), it says that it is going to be used as an “Industrial Use Facility”:

The applicant is proposing an Industrial Use facility along with associated improvements.

Tesla is not directly named on the application, but Michael Loftis of engineering firm Kimley-Horn is named as the applicant, which he and the firm also were named as for previous construction permits at the Gigafactory Texas project. The project is also listed as being on a parcel of land next to the Colorado River where Gigafactory Texas is located.

In the green below, you can see all the land acquired by Tesla and the orange dot is where the main building is located:

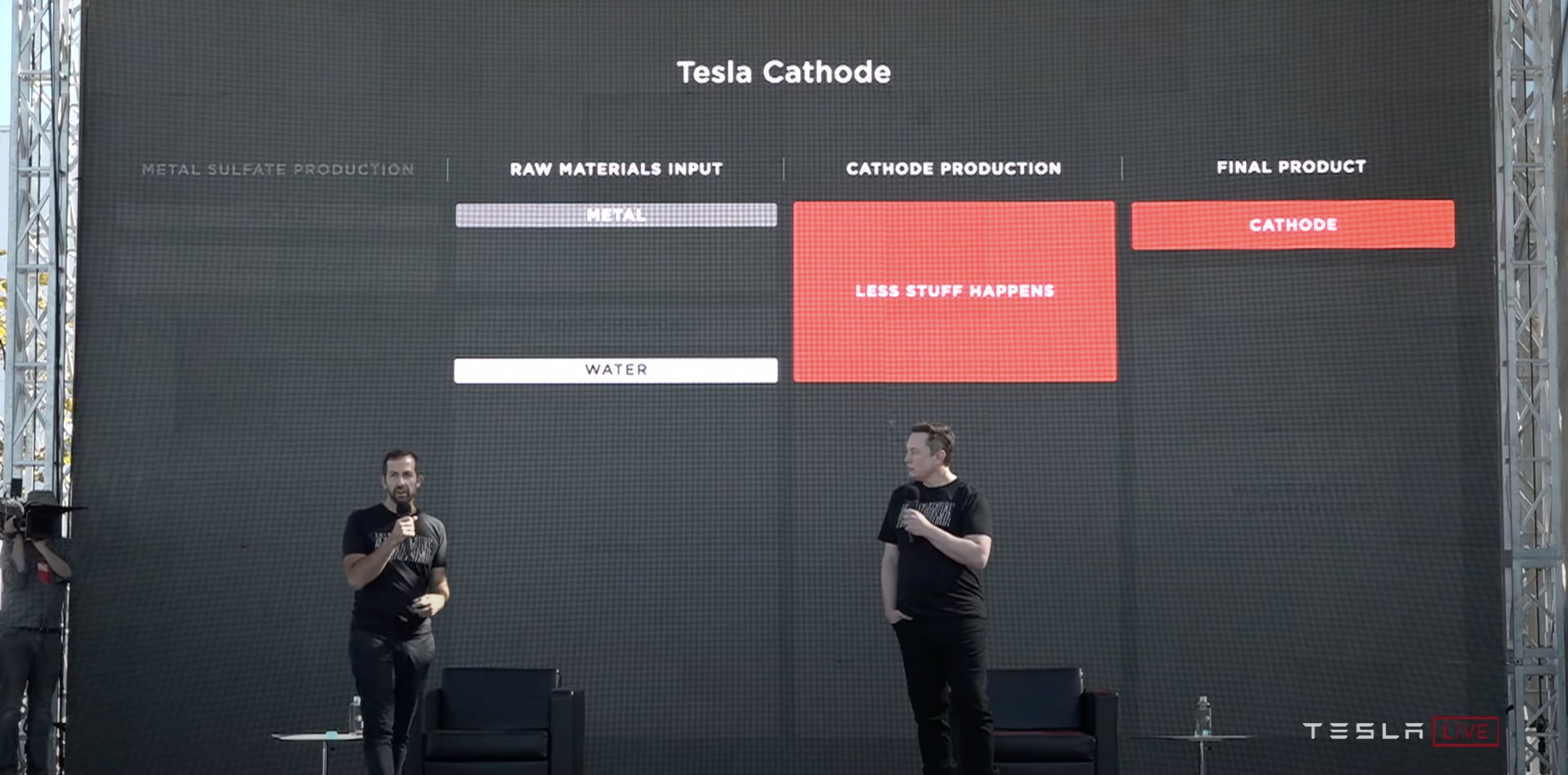

From the name of the new project, it is fairly clear that it is going to be for a cathode production factory. Tesla originally announced plans to build its own “cathode facility” during its “Battery Day” presentation in 2020.

Drew Baglino, Senior Vice President of Engineering, said at the time:

We’re gonna go and start building our own cathode facility in North America and leveraging all of the North American resources that exist for nickel and lithium, and just doing that, just localizing our cathode supply chain and production, we can reduce miles traveled by all the materials that end up in the cathode by 80%.

Tesla has since made moved to secure lithium and nickel supply from North American sources, including deals with Piedmont Lithium and Talon Metals. Several additional similar deals are expected in the coming years to accelerate the production of critical battery metals in North America.

At Battery Day, Tesla unveiled a new cathode chemistry that allows for a much more simple and cheaper production.

It was later revealed that Tesla acquired the technology from a Canadian startup.

In an update on its progress in producing its new 4680 battery cell last month, Tesla confirmed that it has already deployed battery manufacturing equipment at Gigafactory Texas and some are already in operation. A cathode manufacturing facility next to the factory would localize more of the battery cell production and could help achieve greater volume.

Tesla has previously talked about producing over 100 GWh of battery cells at Gigafactory Texas.

FTC: We use income earning auto affiliate links. More.

Comments