Researchers at Harvard University have developed a solid state battery that can be recharged in 10 minutes, and now it’s got Series A funding to scale production.

October 23 update: Adden Energy has raised $15 million in a Series A round led by At One Ventures with participation from Primavera Capital Group, Rhapsody Venture Partners, and MassVentures to scale production and bring solid state battery technology to car manufacturers.

The company will use the funding to construct a roll-to-roll pilot line production facility at its headquarters in Waltham, Massachusetts.

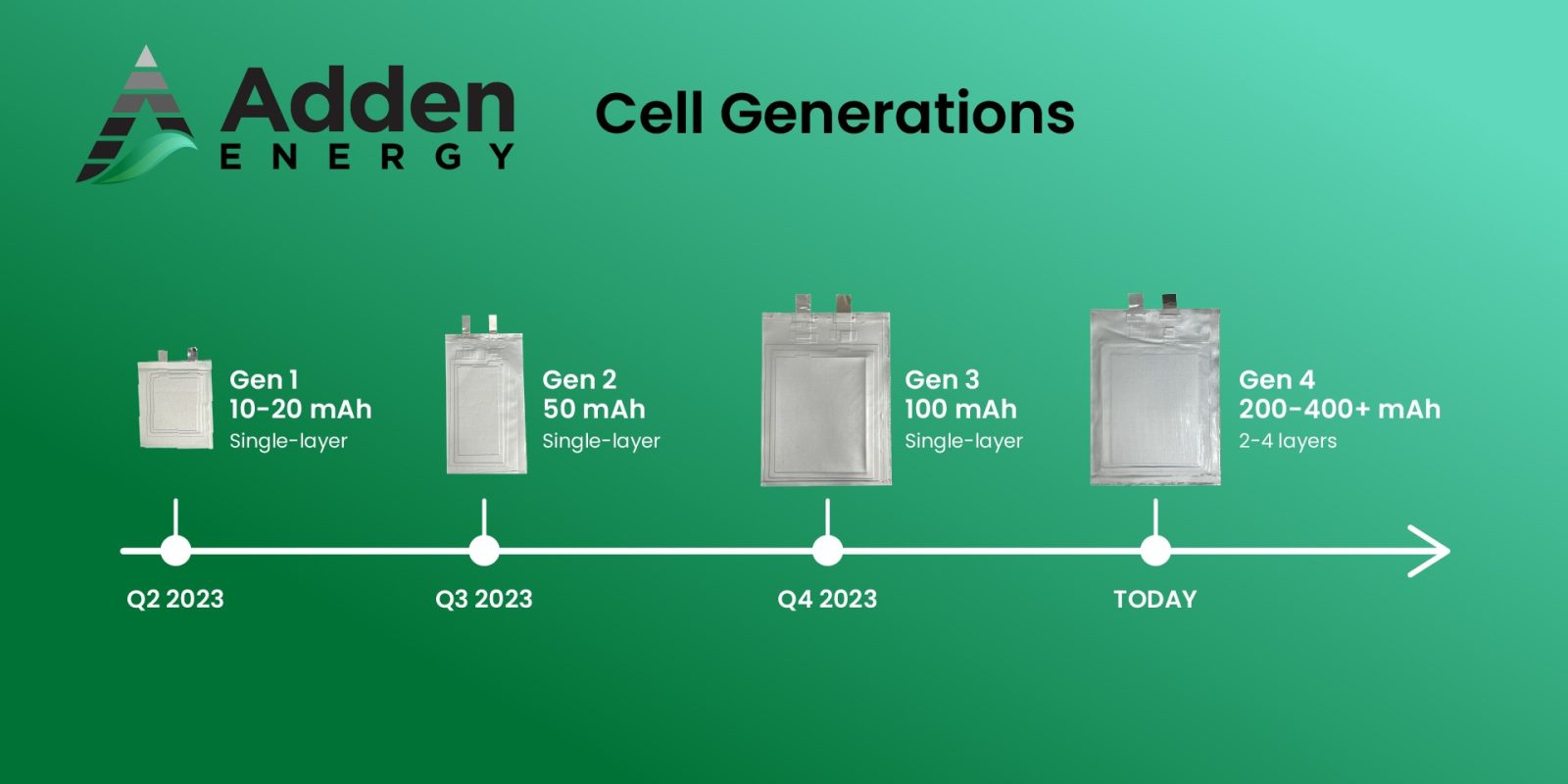

Adden Energy has already demonstrated technology that can deliver its battery in EV-compatible, commercially compatible pouch cell form-factors; this Series A-funded production line will enable it to scale the size of the batteries 100x.

Laurie Menoud, partner at At One Ventures and board member at Adden Energy, said, “Our investment in this technology is a signal of how important we know this to be, and it’s also our confidence level in Adden Energy’s ability to win market share through competitive unit economics. With the added energy density of lithium metal anodes, the cost per kilowatt hour is going to drop by 30%, and that is going to be a significant driver of adoption.”

Adden Energy says its next-generation batteries are on track to reach the goal of EV parity with internal combustion engines by 2028.

Harvard’s latest solid-state battery breakthrough

January 15, 2024: The lithium metal battery researchers developed at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) can also be charged and discharged at least 6,000 times — more than any other pouch battery cell.

The research published in Nature Materials describes a new way to make solid-state batteries with a lithium metal anode. Xin Li, Associate Professor of Materials Science at SEAS and senior author of the paper, said:

Lithium metal anode batteries are considered the holy grail of batteries because they have ten times the capacity of commercial graphite anodes and could drastically increase the driving distance of electric vehicles.

Our research is an important step toward more practical solid-state batteries for industrial and commercial applications.

One of the biggest challenges in designing solid-state batteries is the formation of dendrites on the surface of the anode. Dendrites are projections of metal that can build up on the lithium surface and grow like roots into the electrolyte. They pierce the barrier that separates the anode and cathode, causing the battery to short or even catch fire.

The dendrites form when lithium ions move from the cathode to the anode during charging, attaching to the surface of the anode in a process called plating. That creates an uneven, non-homogeneous surface on the anode, and allows dendrites to take root.

When discharged, that plaque-like coating needs to be stripped from the anode, and when plating is uneven, the stripping process can be slow and result in potholes that induce even more uneven plating in the next charge.

In 2021, the team designed a multilayer battery that sandwiched different materials of varying stabilities between the anode and cathode. This design prevented the penetration of lithium dendrites by controlling and containing them – but it didn’t stop them altogether.

But in this latest research, the researchers stop dendrites from forming by using micron-sized silicon particles in the anode to constrict the lithiation reaction and facilitate homogeneous plating of a thick layer of lithium metal.

In the Harvard researchers’ design, when lithium ions move from the cathode to the anode during charging, the lithiation reaction is constricted at the shallow surface and the ions attach to the surface of the silicon particle, but don’t penetrate further.

“In our design, lithium metal gets wrapped around the silicon particle, like a hard chocolate shell around a hazelnut core in a chocolate truffle,” said Li.

And, because plating and stripping can happen quickly on an even surface, the battery can recharge in about 10 minutes.

The researchers built a postage stamp-sized pouch cell version of the battery, which is 10 to 20 times larger than the coin cell made in most university labs. The solid-state battery retained 80% of its capacity after 6,000 cycles, outperforming other pouch cell batteries on the market today.

Top comment by Dan B

Exciting. I'm just glad there's so many people on this planet who are smarter (way smarter) that I am. Reading this just made my head hurt a little. haha. Anyhow, stories like this are what makes my day. The advancements in battery electric vehicles are moving so fast it seems and before you know it we will have those EV's that will charge in 5 minutes (20 to 80%) and go 400 + miles on a charge.

Harvard Office of Technology Development licensed the technology to Adden Energy, a Harvard spinoff company cofounded by Li and three Harvard alumni. Adden Energy has scaled up the technology to build a smart phone-sized pouch cell battery.

Electrek’s Take

This is yet another milestone achieved in the solid-state battery saga. The ultimate challenge is still bringing them to mass-production at a lower price than lithium-ion batteries. That will be the real game-changer for EVs.

If you’re an electric vehicle owner, charge up your car at home with rooftop solar panels. To make sure you find a trusted, reliable solar installer near you that offers competitive pricing on solar, check out EnergySage, a free service that makes it easy for you to go solar. They have hundreds of pre-vetted solar installers competing for your business, ensuring you get high quality solutions and save 20-30% compared to going it alone. Plus, it’s free to use and you won’t get sales calls until you select an installer and share your phone number with them.

Your personalized solar quotes are easy to compare online and you’ll get access to unbiased Energy Advisers to help you every step of the way. Get started here. –ad*

FTC: We use income earning auto affiliate links. More.

Comments