Volvo Construction Equipment (CE) is putting data at the heart of its decarbonization efforts as it invests in advanced telematics and beefs up its carbon footprint reporting.

Volvo Group has purchased a 22% ownership stake in VizaLogix, a software-as-a-service (SaaS) company that specializes in vehicle telematics and data collection. In addition to providing real-time machine monitoring and enhanced technical support capabilities, the telematics data will help to inform the industry’s most extensive catalogue of Product Carbon Footprint (PCF) reports – making it easier for customers to take active steps to reduce their environmental impact.

“VizaLogix provides brand-neutral SaaS solutions that are easy to integrate and use, helping fleets, dealers and OEMs make smarter decisions,” said Scott Young, head of region North America, Volvo, in a statement. “Volvo recognizes that services are growing to be just as important to fleets as their machines, and our investment in VizaLogix extends our commitment. It’s by combining the right machine with the right services that users get the best solution for their needs.”

The PCF reports released by Volvo confirm that electric machines are a more sustainable choice compared to conventional, diesel-powered machines (which, it should be noted, Volvo also sells — and at a higher per-unit profit than EVs). The reports look at a vehicle’s greenhouse gas emissions throughout its projected life cycle, and cover all steps from the extraction of raw materials, component manufacturing and machine assembly, through to battery recycling and end-of-life salvage. The principles of the methodology are based on both the global ISO standard for Life Cycle Assessment and the Greenhouse Gas Protocol.

“Customers are now rightly looking with absolute scrutiny at carbon performance – on a par with other considerations like cost and quality,” says Rickard Alm, Head of the Life Cycle Assessment (LCA) program at Volvo CE. “With our Product Carbon Footprint reports, we are making it easier to have quick access to the information needed and enabling them to act on their decarbonization ambitions.”

You can explore Volvo’s initial PCF reports here. Be sure to bookmark the page, though — there will be more to come.

Why the VizaLogix thing is cool

As for VizaLogix, their acquisition is going to enhance not just Volvo CE’s reporting, but their ability to support their machines in the field and, ultimately, keep them running longer. The company’s products enable support for mixed fleets and mixed data connections, including:

- Vantage Point: a mining app that provides real-time data on crucial site metrics like idle times, cycle counts, and tonnage delivered

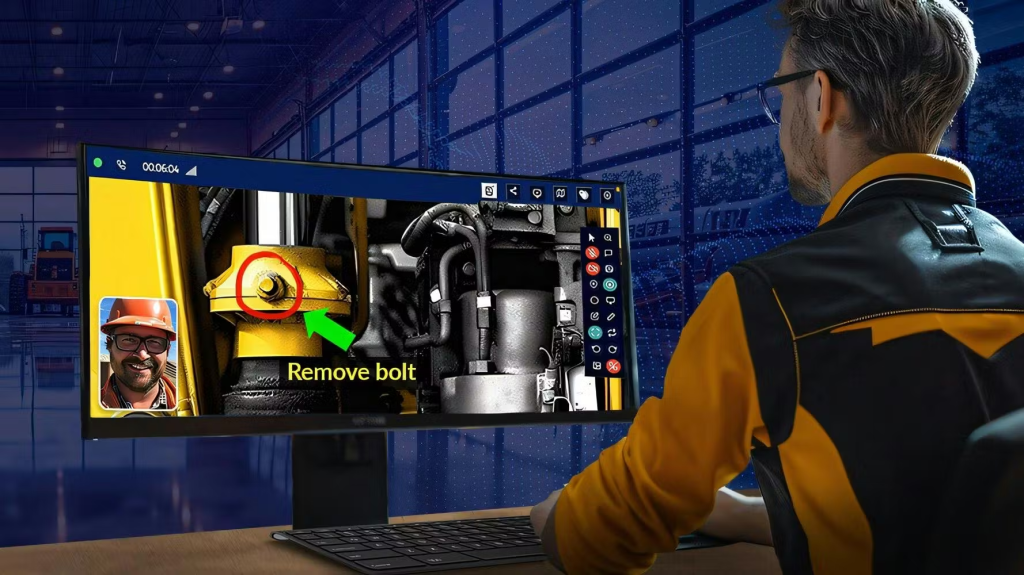

- TethrIT Now: a real-time collaboration tool that works over multiple channels, allowing augmented reality video calls that featuring helpful overlays that let users visually point, highlight, or mark areas of focus for technicians on either end of the call

- TechnicianNow: it’s telehealth for your equipment, enabling a technician to troubleshoot and diagnose machines through a mobile app that connects them with real-time parts availability to give fleet managers a comprehensive understanding of what’s happening, why, and when it will be fixed

Moving forward, the information gathered with these digital tools will help inform parts purchasing and technician training, and ultimately help build confidence in electric equipment — a crucial step in convincing fleet operators to buy electric.

Electrek’s Take

Volvo is serious about decarbonization and sustainability, and they’re pushing hard to have electric options in all their CE product lines.

The Heavy Equipment Podcast was recently joined by Mats Sköldberg, head of technology for Volvo Construction Equipment, to chat about the company’s all-new, battery-free EW240 Electric material handler (above), the expansion of their electric offerings, and more.

You can check out that HEP-isode, below, and let us know what you think of Volvo’s commitment to data in the comments.

FTC: We use income earning auto affiliate links. More.

Comments