This massive Liebherr electric excavator reached a major operational milestone earlier this month when it moved its one millionth tonne of dirt. And now, its buyers want more!

That’s right, gang – since we first covered the converted mining excavator back in January it’s been hard at work. And now, after its initial 90 day “break-in” period operating at partial capacity while the site team familiarized themselves with the new tech, it’s operating at full speed at Fortescue’s Christmas Creek mine in Western Australia.

The Liebherr is working so well, in fact, that Fortescue is planning on order two more examples of the mighty electric earth-mover.

“This is such an exciting milestone for Fortescue and our decarbonisation journey. Importantly, we’ve been able to achieve this while maintaining our high safety standards,” says Fortescue Metals CEO, Dino Otranto. “We will have two additional electric excavators commissioned by the end of April. Once we decarbonize our entire fleet, around 95 million liters of diesel will be removed from our operations every year, or more than a quarter of a million tonnes of carbon dioxide equivalent.”

Big work needs big power

Top comment by Grant

It’s great to see Fortescue making good on its pledge to go electric and go renewable. The owner did a piece a few years ago on sixty minutes I think, and he seemed sincere.

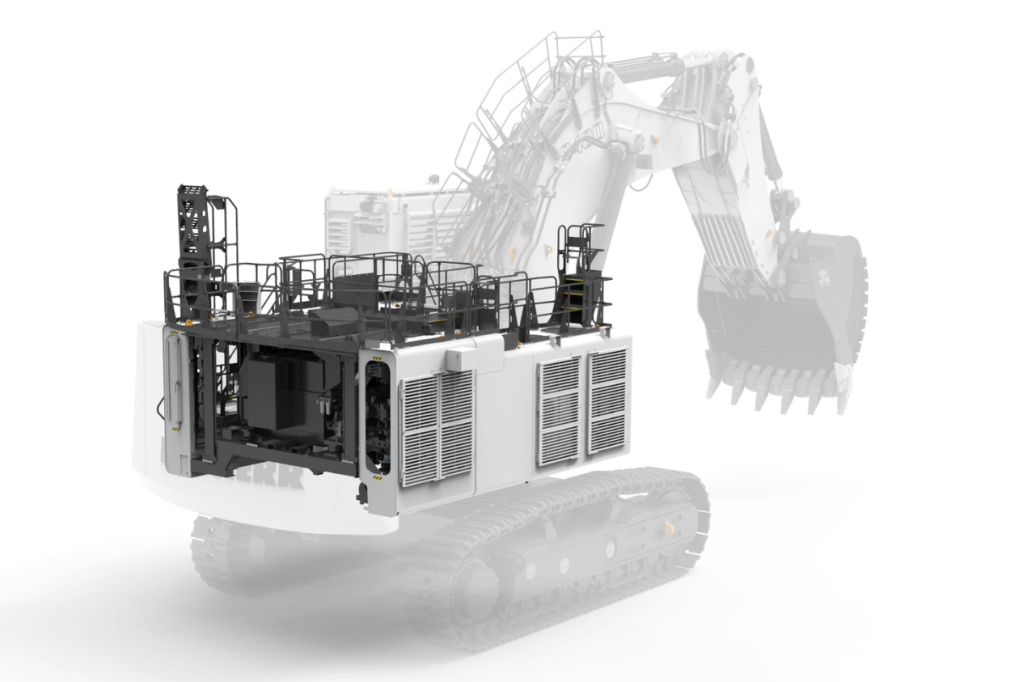

Moving more than a million tons of earth and rock takes a lot of energy. To keep its batteries topped off, the re-powered Liebherr R 9400 E electric excavator operates off blend of renewable solar power and a 6.6 kV substation pumping electrons through more than two kilometers of high voltage trailing cable.

Eventually, though, Fortescue plans to power its equipment completely from sustainable sources. “In line with our commitment to eliminate emissions across our mining operations,” reads the company’s statement. “The intention is that all electrified mining equipment will eventually be 100 per cent powered by renewable electricity.”

Electrek’s Take

Covering an electric pilot program is always fun, but all too often the results of these initial experiments aren’t publicized – or else, don’t directly lead to sales. To their credit, Liebherr is lucky to have a customer in Fortescue that’s willing to put their cards on the table here, trumpeting the re-powered excavator’s success and even announcing its plans to order two more electric machines publicly.

They won’t have to wait long, either. Because Liebherr takes a modular approach to building its larger mining equipment, a diesel-drive excavator like the R 9400 can be completely re-powered to electric in a matter of weeks.

FTC: We use income earning auto affiliate links. More.

Comments