Battle Motors invited us out to Irwindale Speedway to drive its powerful electric garbage trucks around the racetrack, and we came away dreaming of quieter, cleaner neighborhoods that feel like they’re just around the corner.

Garbage trucks have been considered ripe for electrification for some time now, as the duty cycle of a garbage truck lines up very well with the strengths of electric vehicles. They do a lot of starting and stopping, which means the regenerative braking and lack of idling on an EV are beneficial. They carry a lot of weight, meaning they need ample low-end torque. And they do predictable daily routes before heading back to a depot, ensuring a place to charge and allowing buyers to right-size the battery based on route length.

In the face of new truck regulations both on the California state and US federal levels, the rush to electrify heavy-duty vehicles has never been more urgent.

Battle Motors is a relatively new player, but in 2021, it acquired Crane Carrier Company, which has operated since 1946, building chassis for construction, refuse collection, and other industries. The company now has a full slate of electric chassis/cab combinations for “vocational” applications.

So far, Battle Motors has sold EV trucks to the cities of Los Angeles, New York, and Plano, Texas. EVs have made up about 5% of its sales this year, but it expects EVs to make up 20% of sales next year.

The event was put on by Velocity Truck Centers, a commercial truck dealer network that serves the Southwest US and distributes Battle Motors’ electric trucks. (We also drove Battle Motors’ all-electric street sweeper, the first put into service in the US, at the same event.)

And sure, track performance doesn’t matter for a garbage truck, but these vehicles do need a lot of power and can benefit from being more nimble, not needing to shift through so many gears, not slowing down traffic on city streets when going to and from the depot, and so on.

There is, unfortunately, still a persistent feeling among some crowds that electric motors don’t have enough power for heavy-duty applications (which couldn’t be further from the truth – the heaviest-duty applications, like freight trains, cruise ships, and mining trucks will often use electric drive, just fueled by diesel generators), so demo days like this are useful for fleet operators to get some hands-on experience.

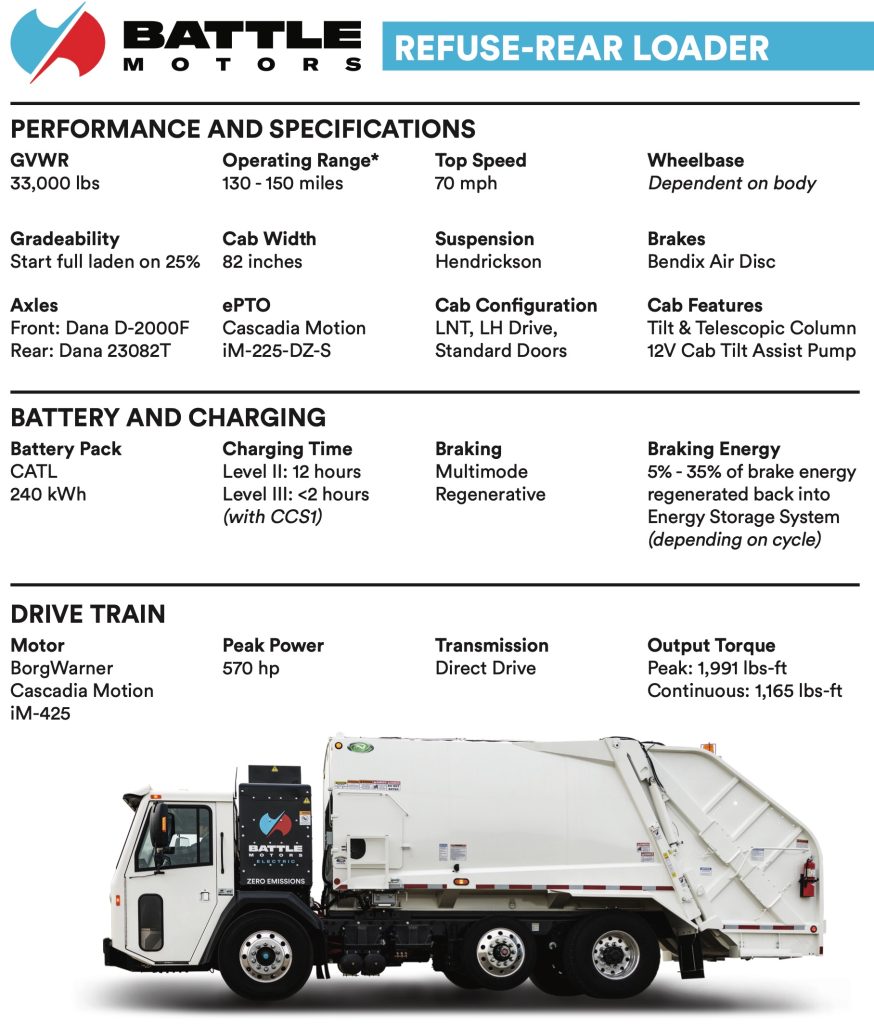

Battle Motors’ trucks have either a 240 or 400 kWh battery and 442-570 horsepower, depending on configuration. Range depends on use and configuration, but with these two battery options, buyers will be able to right-size their pack for their application.

The trucks we drove felt smooth and quick on the track despite their 30,000+ lb. weight, with no problem getting up to speed – or down from it. Regenerative braking was strong; we saw up to 250 kW of regen being applied when we let off the accelerator. This helps make the vehicles more efficient, reduces maintenance due to lower brake usage, and reduces one source of noise, which is particularly beneficial for neighborhood operation. It’s also nice for drivers who don’t need to move their leg around to press the brake pedal as much (a minor thing, but compounded over several 8 hour days, it can add up).

These vehicles weren’t exactly quiet because while the diesel engine has been deleted, there’s still plenty of machinery associated with loading garbage into the truck, which will still make just as much noise as in diesel-powered versions. But they are quieter than the diesel versions, and every little bit of noise reduction helps in a neighborhood (especially with the modern predilection towards work-from-home – trash days are utter chaos in my neighborhood).

Battle Motors’ philosophy has been not to shake the boat too much when it comes to laying out powertrain parts, choosing to mount the motor up front and deliver power to the axles through a driveshaft rather than an e-axle. For the garbage trucks especially, putting the motor in the rear would risk having food refuse and other gunk potentially falling onto it in the course of operation, which could lead to corrosion or result in varmints chewing up cables or something. Plus, in a time when EVs will necessarily only be part of a fleet (so far), it makes it easier for fleet mechanics to work on alternate powertrains when the rest of the parts are similar.

The interior had about what you’d expect out of a garbage truck. Various switches to operate equipment, air-ride seats, command seating positions with big flat windows, and so on. But electric vehicles can be more comfortable for drivers, especially with so many hours in the truck, because the lack of a rumbling diesel engine means less vibration, less exhaust, and less noise, which makes working hours generally easier on the body.

The digital info cluster is a large, detailed LCD screen running Battle Motors’ “rEVolutionOS.” The trucks use MobilEye’s Shield+ system for collision avoidance and blind spot detection, helping to increase safety.

Electric heavy-duty trucks are still expensive, costing twice as much (or more) as comparable diesel vehicles. Companies can generally recoup these costs with drastically lower running costs, including fueling and maintenance, and the difference is even greater when environmental costs are taken into account.

That last point is why governments have offered huge incentives to reduce upfront prices of heavy-duty vehicles, to the amount of tens or hundreds of thousands of dollars per truck, to the point where post-incentive pricing can be quite similar to diesel vehicles in places like California, where lots of incentives exist.

And it’s about time, too. Heavy-duty vehicles make more than their fair share of pollution, and for things like diesel garbage trucks, that pollution happens directly in communities where people spend most of their time (and this pollution also harms refuse workers, who are around it every day). The quicker we can clean that up, the better.

FTC: We use income earning auto affiliate links. More.

Comments