As Tesla CEO Elon Musk pleaded for more battery infrastructure in America, we toured Porsche’s incredibly advanced Smart Battery facility in Slovakia.

BACKGROUND

Porsche is continuing its “foundational tech” communication campaign (Innovation in sync: the road to the electric Cayenne) for the all-electric Cayenne. The experience from my first session in October 2025 is captured here.

This session, they invited us to learn more about the production process and witness some of the first vehicles roll off the production line.

Over the course of 36 hours, we got a tour of the brand new Smart Battery Shop as well as the assembly facility where all 3 Cayenne models go from a bunch of parts from all over the world into a complete vehicle and onto trains to be shipped out.

This session focused on:

- Innovation in manufacturing (Automation and streamlined process)

- Capacity (to address demand throughout the chain)

- Flexibility (to address customization and market requests)

- Quality (Testing and iteration built into the process)

THE SMART BATTERY SHOP

Just days before Elon Musk was pleading in Tesla’s quarterly earnings report for more battery infrastructure in the United States, we were touring Porsche’s brand-new, almost completely autonomous smart battery shop in Horná Streda, Slovakia.

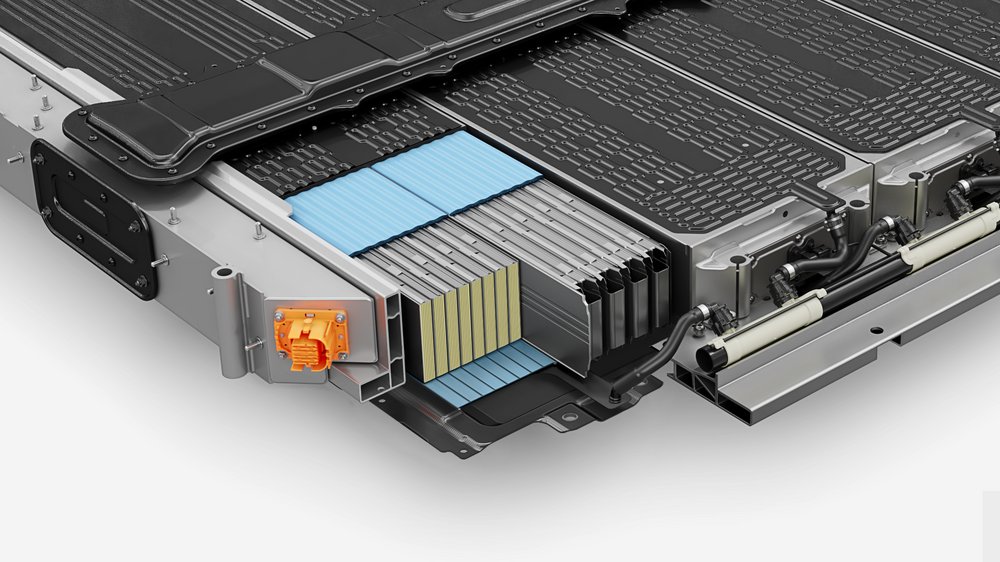

This is where LG cells (pouches) come in one side, and mostly complete, fully tested battery modules come out the other. These are sent to another facility where the 113kWh battery pack capable of an 850 kW (1,156 PS) power output is fully completed.

The tech and reasoning behind aluminum polymer foil pouch cells with the composition of graphite, silicon, Nickel-manganese-cobalt-aluminum (NMCA) cathodes, etc., is a deep dive and was not the topic of these sessions.

Short story – pouches are a bit harder to work with but have a higher energy density, are lighter, and have different cooling characteristics that Porsche feels result in a better power-to-weight ratio for their use case.

So they designed with this in mind.

The entire process and production was designed in-house by Porsche and (through a web of subsidiary companies and partnerships) remains notably close to Porsche itself compared to other components and factories in the process.

It would not be a stretch to say that the use case the Porsche team is addressing with the Cayenne Electric would also apply to any other make or model within the VW group.

This is because battery pack capacity and performance are inextricably tied to practical needs such as thermal management and discharge/recharge management.

Building a decently heavy, high-performance SUV that goes fast for long periods of time, can regen, can tow, can climb, can go offroad, can rapid-charge, and keep doing all of this over and over – presents challenges Porsche feels it is uniquely positioned to address with this battery approach.

But you need to make a TON of batteries to make this feasible.

Observing how the complexities of scale, volume, and quality control have been managed throughout the decades, it is always rooted in some form of station / stage-driven assembly process. Steps that build on other steps, and it is no different here, apart from the obvious absence of humans and sheer size of the operation.

Small objects (consumer electronics) are straightforward for completely autonomous lines.

Huge objects benefit from being assembled and welded by a few machines and shuttled to other stations by people or a forklift.

This is not that.

40k sq meters of pretty much completely robotic manufacturing is hard to describe.

For those who game – it is the closest to a real life Factorio factory I have witnessed in action.

Not just because of modularity, but how there seems to be a connectedness to the entire chain. After each node in the process the components go overhead and move to the next node – autonomously.

You get the sense everything is finely tuned with capacity managed in sync and in real-time. Perhaps predicting needs down or up the line without people involved in the request process at all other than saying “Here is a truckload of components.” and the factory saying. “OK, tomorrow at 9am you can pick up your completed modules at loading dock 4”.

There are almost 280 robots and 150 people employed (organized over 2 shifts so ~75 people per shift).

They are not up to full production yet, but we could see from the sections in operation that humans casually stroll from node to node checking up on the robots, but are not actively involved in battery construction.

Imagining the environment at full operation when ~75 people (per shift) are spread out inside a 40k sq meter space packed with stations full of robots kicking out several hundred modules a day – it will feel calm or perhaps even “empty” compared to a typical manufacturing process of this size and scale.

A lighter human support system is practical in this situation.

Physical tolerances aside – the components are volatile.

There are 8 cells (pouches) per stack; 4 stacks per module and 6 modules come together for a Battery pack with a potential of 113kWh.

If you can keep people away from touching, positioning, stacking, laser welding, and “wiring” steps until everything is nicely contained in a protected, balanced module – better for all.

Every step along the way, the pouches, stacks and modules are tracked, tested and treated with respect while the humans remain on the other side of protective see-through barriers. It never felt unsafe and in fact felt totally benign as we strolled through the rows of machines and battery parts with massive energy potential. Certainly the sense of safety is the result of people doing a bunch of math evaluating the risk and action needed in case of a thermal runaway or other issue.

As the line progresses – the modules have stabilization foam, thermal gap filler and cooling plates added to make them self-contained, transportable and ready to be added to a complete battery pack (done in another facility closer to the assembly factory.)

Once assembled the “kit gloves” go from managing the volatility of pouches to protecting the efficacy of the cooling solution.

It was mentioned throughout our tours how much attention is paid to protecting the cooling solution on the modules at the battery facility, for transit and again at the assembly plant regarding the cooling plates for the overall battery pack. It is worth extra consideration and care as the thermal system is built into both sides (top and bottom) of the pack.

This highlights how thermal management is a key consideration with the design and essential to the high performance the team expects from this pack (and the vehicle as a whole) to deliver.

Porsche says they will be able to track, monitor (and to some degree) update components of the battery well into the future when the vehicles are out in the wild. This will serve to both learn from and refine the packs in real world applications but this data can come right back into the plant and be used to make refinements for future packs.

This leans into another key concept of this battery pack : the ability to diagnose and service it.

To have the entire history down to a cell and (if needed) easily drop the pack from the vehicle with a “few bolts” and service (or likely replace) a module instead of an entire battery pack.

The interest to learn from and continue to refine seems to be built into the entire flow as much as quality.

Once all tested again – it is packed up and sent down the road to another facility we visited the next day.

THE VOLKSWAGEN GROUP MULTI-BRAND SITE

Since 2016, all Cayenne vehicles have been assembled in the Volkswagen Groups Multi-brand site outside of Bratislava, Slovakia.

This is an impressive facility that has been a part of the group since 1991 and has since expanded to about 2 million square meters of factory space spread across many halls.

In 2024 – a total of 341,111 vehicles were produced, almost half of which were equipped with electrified drive systems.

In 2025 – 450,000 vehicles were produced making it the second largest plant for VW with Twelve models from four group brands at the multi-brand site.

As this relates to the Cayenne Electric

- This facility has been in full production of Cayenne since 2017.

- Last year the 1.5 millionth Cayenne was completed there

- They concurrently run three “segments” or assembly lines (3 factories in 1)

- ONE of those three segments is running the Cayenne with a capacity of around 180,000 units per year

- The Cayenne line is currently assembling all models, variants and customizations of the Cayenne on a single line.

—-ASSEMBLY HALL—-

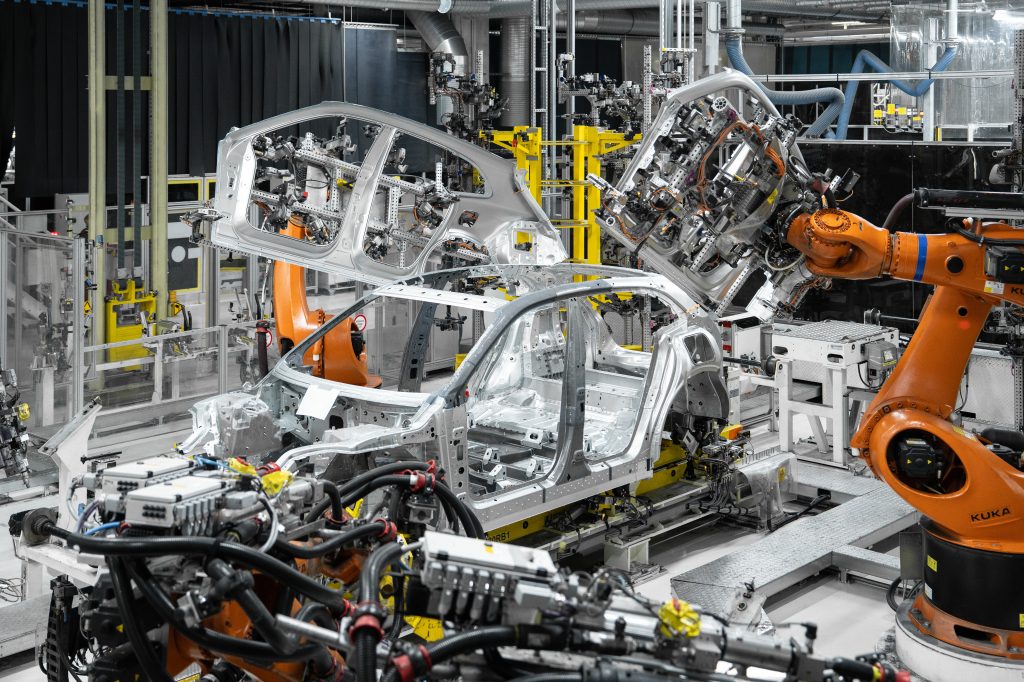

The assembly hall is huge and houses three final assembly “segments” or lines.

The lines are advanced with the ability to assemble multiple customizations of the vehicle one after the other (similar to other plants), but in fact the Cayenne line is demonstrating a fundamentally different powertrain, chassis and body on the same line as it is currently assembling the ICE, Hybrid and now the All Electric mixed in together.

With this approach, Porsche feels confident it can address capacity and be flexible to market demand regardless what kind of power train resonates with drivers in the future.

Before the body is “wedded” to the “Skateboard Chassis”, we get a glimpse into the radical difference in physical complexity between the three power trains.

Sure – the technology behind all the elements of the all electric is front loaded, many innovations, lots of thinking, new problems to solve (heat, power capacity, etc.), however once on the line, the all-electric looks so much simpler and straightforward compared to the Internal Combustion model. In fact, the non-electric vehicles get split off for one additional section of the line the all-electric can skip.

Even with all this creative thinking on what parts show up where and when on the line – the assembly line is likely a familiar sight for those knowledgeable with auto manufacturing techniques established for many years (the moving floor and people actively involved in putting in dashboards and doors etc), component tracking, etc.

However, for the Cayenne Electric, the hall before assembly is VERY different from the other models and Volkswagen production.

—-PLATFORM HALL—-

In the “Platform Hall”, the Volkswagen Group and Porsche demonstrate another commitment unique to the all Electric Cayenne and the future of auto manufacturing.

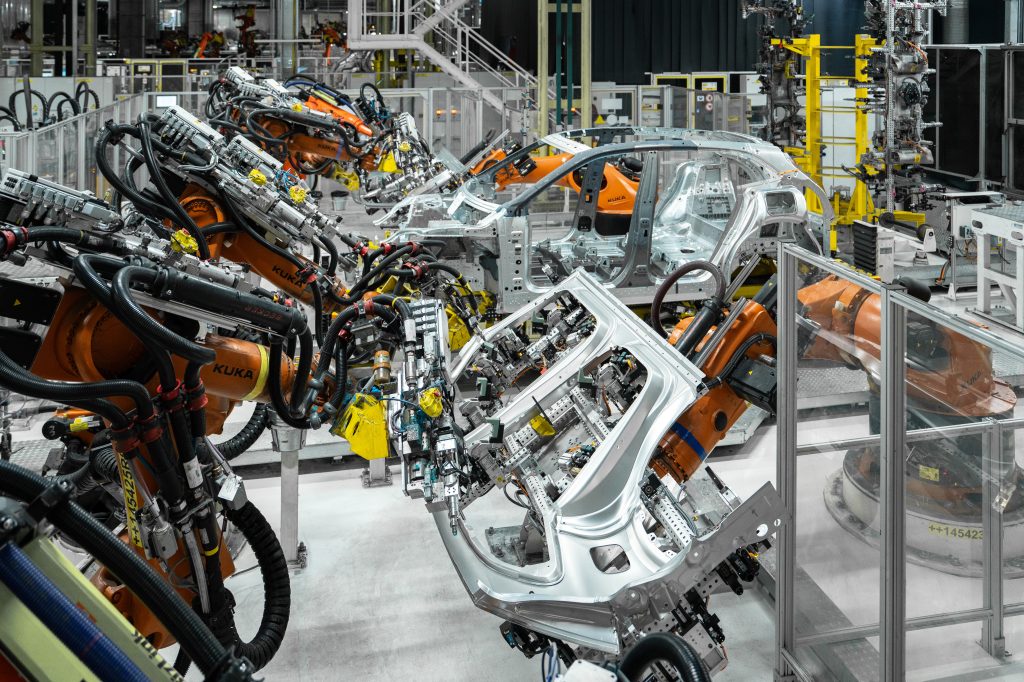

It was like stepping back into the future. This hall was much more like the Smart Battery Shop from the previous day than the assembly hall we had just left, but with MUCH larger parts flying around.

This is the hall where the “Skateboard Chassis” is constructed with the support of a main press capable of 91,000 kilonewtons (kN).

This is a HIGHLY automated environment with lots of robots and few humans. This time moving around very large components (the chassis) – shaping, welding, gluing, bonding.

After which the robots fit the side panels, roof, doors, bonnet and tailgate before being conveyed over to another hall and joining the other Cayenne models for body work.

When in full production, there will be about 140 people supporting around 500 robots. Porsche and the Volkswagen group are working hard to address scaling production techniques with solutions close to the source of assembly with this hall.

It was not in full action when we walked through, but the component stock looked topped up, all stations looked primed, and the machines all had green lights as if they could be active at any time should the need arise.

After the skateboard chassis is complete, it is conveyed to the body shop where it enters the process with the other Cayenne models eventually heading to paint which we did not tour this time.

THE VIBE

It would be easy to focus on the economic issues and management turmoil frequently reported about Porsche, EVs and the industry and let that overshadow this project.

If you only read headlines saying Porsche has taken too big a risk in electric, you would understand why I keep hearing:

“I heard Porsche is giving up on Electric.”

That is not what I saw and felt.

Unlike many in the industry, they are not saying:

“We hope to build..” or

“We plan to look into..” or

“In the future we will have…”

No – They are saying:

“It is here. Let us show you!”

They are sharing what they have done and demonstrating what it does.

It is in production and the big nasty complex stuff has been (or is actively) being addressed. All electric Cayenne’s are rolling off the line right now.

That was clearly the point of these sessions – They are showing that they can deliver through the entire chain and they appear earnestly proud of it.

The investment has been made, the factories are built, the teams are working, this vehicle exists and can be produced at scale.

More importantly, The team is obviously proud.

Everyone I met, from Engineers to assembly technicians, factory designers to the Pro Drivers, each is excited and has a huge amount of pride in both how their area of expertise is applied to the Cayenne Electric but also the resulting end product.

This has come through in both of the sessions I have attended so far.

I am sure the team is coached and they know they are talking to people who are going to write about the things they say and read into how they act – but you can tell when people are talking about their job and reading from “talking points” versus the wash of excitement people have as they talk about something they believe in, or when the sparkle in the eye as they partially overshare is genuine.

The people behind Cayenne Electric believe in it, are excited about it, feel it delivers on (or will exceed) the specs they say and seem to look forward to people experiencing it for themselves.

Top comment by Aigars Mahinovs

Porsche team are really strong and translate their capabilities to BEV drivetrains and packaging very well. The only thing still hobbling the whole VW Group is software. It is hard to get good, flexible and evolving software from outsourcing contracts. It is very hard to develop it in-house. And the hardest part is keeping the software features and development synced to the many models and thousands of variations that Porsche customers expect to have in their cars. The car startups never even try to do that - they just deliver the same software to all cars and hope it mostly works. That stops working when you have dozens of models across a hundred countries with thousands of configurable knobs at order time.

I get the feeling that the VW group does not particularly care which Cayenne models sell the most, given the 180k all-model potential capacity next year, but certainly this group within Porsche would like to see a large percentage of that be all-electric. Not just because of the tech or their involvement, but because they feel it is a strong representative for the future of Porsche.

THE TAKEAWAY

- If you want a Cayenne Electric, they will be able to make it.

- The tech and techniques of the all-electric Cayenne will inform other makes and models in the Volkswagen Group (not one and done).

- The commitment to future manufacturing techniques is real.

- The dedication to quality and performance is represented throughout the production process.

A few questions remain (when we get our grubby hands on it):

- Will we get that same feeling of excitement and attachment the team feels?

- How will the specs translate to the real world?

- Will anyone actually take this off-road or tow something, or tow something off-road? 🙂

It seems we are close to finding out.

FTC: We use income earning auto affiliate links. More.

Comments