Tesla has started building Model Y battery packs with its in-house 4680 cells again, more than two years after pulling the plug on the original 4680-equipped Model Y to prioritize Cybertruck production.

But this time, the motivation isn’t revolutionary battery tech. It’s tariffs. And also, Cybertruck’s poor sales mean the program doesn’t consume many batteries.

What Tesla said

In Tesla’s Q4 2025 shareholder update, the company disclosed:

We have begun to produce battery packs for certain Model Ys with our 4680 cells, unlocking an additional vector of supply to help navigate increasingly complex supply chain challenges caused by trade barriers and tariff risks.

Tesla also noted progress on domestic battery production:

We now produce dry-electrode for 4680 cells with both anode and cathode made in Austin. We expect both domestic cathode material in Texas and LFP lines in Nevada to begin production in 2026.

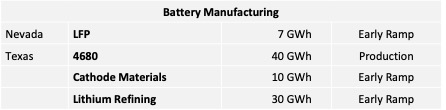

Tesla also now shares this useful table about battery manufacturing in its earnings report:

It’s important to note that these are “installed capacity” and not actual production.

The 4680 saga so far

The 4680 cell has had a turbulent journey since Elon Musk unveiled it at Battery Day in September 2020, promising it would cut battery costs in half and enable a $25,000 Tesla.

Here’s what actually happened:

February 2022: Tesla announced it had produced 1 million 4680 cells at its Kato Road pilot facility in California.

April 2022: The first Model Y vehicles built at Gigafactory Texas with 4680 cells and Tesla’s new structural battery pack started shipping to employees.

December 2022: Tesla confirmed 4680 production had reached 868,000 cells per week, enough for about 1,000 Model Y vehicles.

April 2023: Tesla finally opened public orders for the cheaper Model Y AWD with 4680 cells at $49,990, after a year of selling it as an “off-menu” product.

September 2023: Tesla quietly discontinued the 4680 Model Y AWD, removing it from the configurator entirely. The leading theory at the time: Tesla needed to redirect its limited 4680 cell production to the Cybertruck, which was about to launch.

November 2023: Cybertruck deliveries begin. The truck becomes the only Tesla vehicle using 4680 cells.

2024-205: Cybertruck is a commercial flop and therefore, doesn’t require many battery cells.

December 2025: In a sign of how badly things have gone, Tesla’s 4680 supply chain partner L&F Co. wrote down its $2.9 billion cathode supply deal with Tesla by over 99%, to just $7,386, citing a “change in supply quantity.”

January 2026: Tesla announces 4680 cells are going back into some Model Ys.

A very different story

When Tesla first put 4680 cells in the Model Y, it was supposed to herald a new era of cheaper, more energy-dense batteries that would make EVs affordable for everyone.

That’s not what this is.

Tesla explicitly framed the return of 4680 to Model Y as supply chain diversification, a hedge against “trade barriers and tariff risks.” In other words, if Chinese battery suppliers get hit with tariffs or export restrictions, Tesla wants domestic cell production as a backup.

The $25,000 Tesla that the 4680 was supposed to enable? Musk scrapped that plan entirely.

Electrek’s Take

This is a quiet admission that the 4680 program hasn’t gone according to plan.

Five years after Battery Day, Tesla’s revolutionary battery cell is being repositioned from “game-changing cost breakthrough” to “tariff hedge.” The cell that was supposed to halve battery costs is now being used to navigate trade policy, not to build cheaper cars.

The L&F write-down last month told the real story: Tesla isn’t ramping 4680 production at scale. Cybertruck demand collapsed, and that was the only vehicle using the cells. Now Tesla is putting some 4680 cells back in Model Y, but framing it as supply chain flexibility rather than a return to the original vision.

There’s still progress, Tesla says it now produces dry-electrode cells with both anode and cathode made domestically in Austin. That’s genuine vertical integration that most automakers can’t match.

But let’s not pretend this is what Musk promised at Battery Day. The 4680 was supposed to be the key to Tesla’s future. Instead, it’s become a backup plan.

FTC: We use income earning auto affiliate links. More.

Comments