If you’ve spent enough time riding electric bikes, you quickly realize that power is only part of the draw. Another big part is sound – or more accurately, the lack of it. A smooth, quiet motor can make an e-bike feel refined and premium, while a buzzy, rattly drivetrain can cheapen the experience no matter how strong the specs look on paper.

That’s something Bafang, one of the world’s largest e-bike motor manufacturers, says it has been focusing on for years. And after I took a trip inside their motor testing grounds, I got to see how they do it.

What I saw showed me how the company approaches motor noise reduction – and it turns out that “quiet” isn’t the result of a single trick or material choice, but a system-level engineering problem that starts at the electromagnetic level and runs all the way to how a motor is mounted in the bike frame.

Where e-bike motor noise actually comes from

Motor noise generally falls into two categories. The first is electromagnetic noise – the high-frequency buzzing caused by fluctuating magnetic forces between the stator and rotor. This is often what you hear as a whine under load, especially at higher assist levels.

The second is mechanical noise, which includes everything from gear meshing and bearing operation to imbalance in the rotating assembly and even air turbulence inside the motor housing. On geared hub motors and mid-drives alike, these mechanical sounds are often what riders notice first.

Bafang says reducing noise starts with identifying and isolating both sources, rather than trying to mask them after the fact.

Quiet starts in the magnetic design

On the electromagnetic side, Bafang uses high-precision magnetic circuit simulation to reduce fluctuations in magnetic density inside the motor. By suppressing higher-order harmonics and smoothing out the magnetic field, the engineers aim to minimize vibration before it ever turns into audible noise.

The company also highlights its use of high-quality silicon steel laminations with low magnetic loss, which helps reduce tiny shape changes caused by magnetostriction – a subtle but real contributor to motor buzz that often gets overlooked outside of higher-end designs.

Structure, stiffness, and vibration control

Motor housing design plays a bigger role than many people realize. Bafang says it favors internal rotor layouts and stiffer housings to prevent vibrations from being amplified by the motor shell itself. Tight control over air gap uniformity and lamination quality helps keep the electromagnetic forces balanced, reducing structure-borne vibration.

Equally important is how the motor interfaces with the bike. Vibration-damping mounting structures help prevent motor noise from being transferred into the frame, where it can be amplified and turned into that familiar resonant hum some e-bikes produce under load.

Gears, bearings, and the mechanical side of silence

Inside the drive system, Bafang uses composite material gears designed to damp vibration while maintaining durability. These gears are often self-lubricating and significantly quieter than traditional metal alternatives when meshing under load.

Rotors are dynamically balanced to avoid off-center vibration, and bearings are selected and greased specifically for low-noise operation at the motor’s intended speeds and loads. None of these choices are flashy on a spec sheet, so they often go overlooked, but together they add up to a noticeably smoother and quieter ride.

Measuring silence

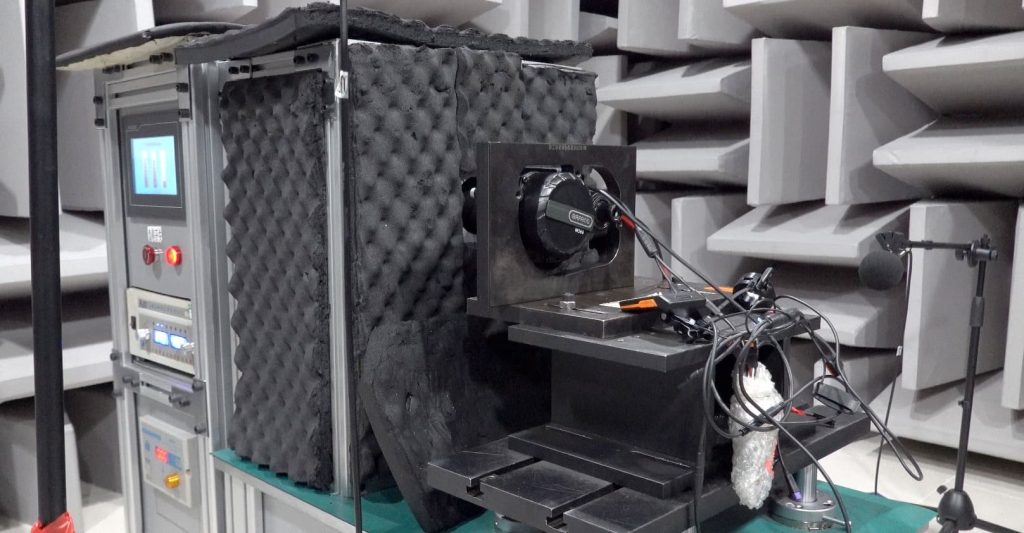

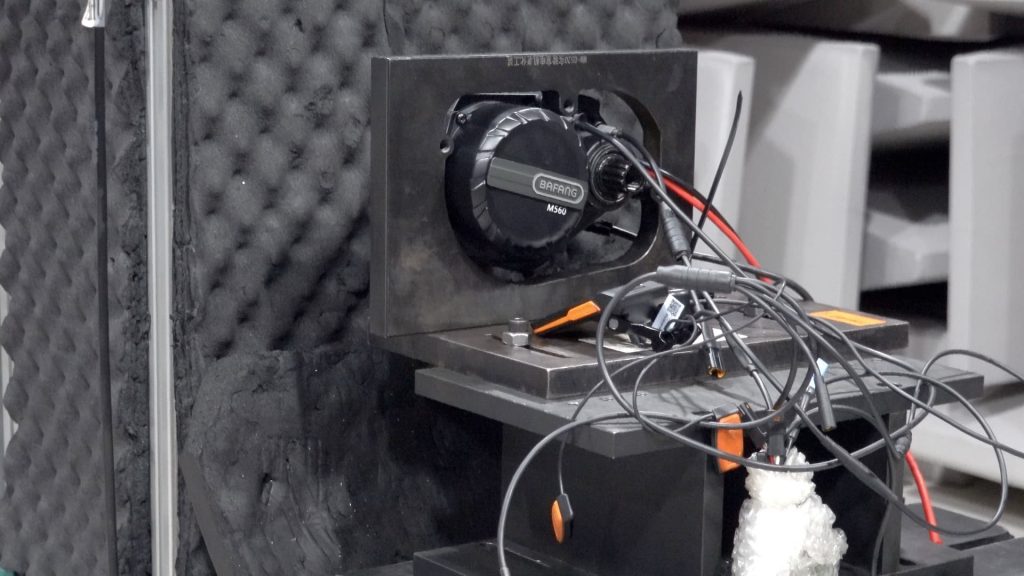

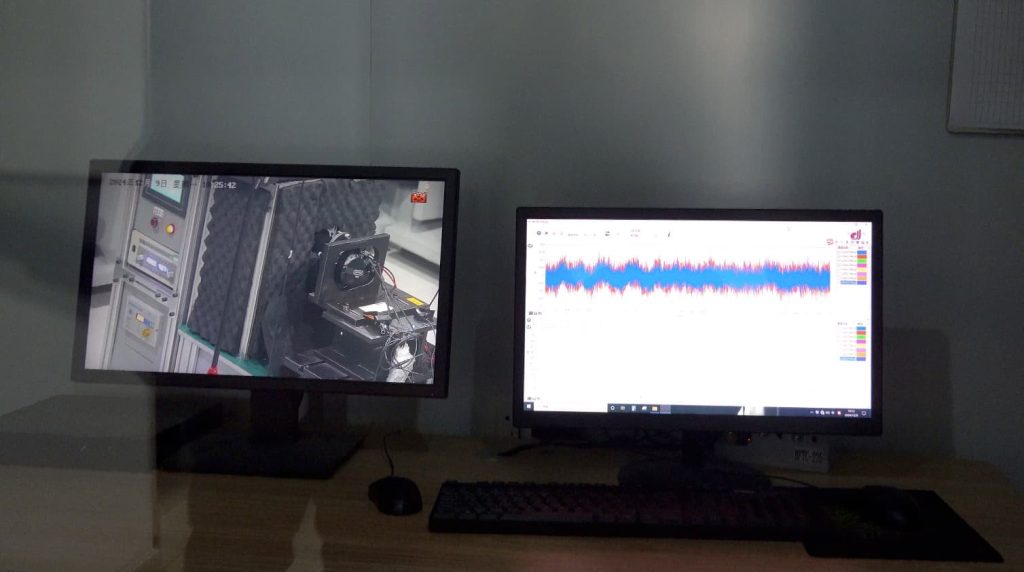

The company operates a dedicated acoustic laboratory with sound-absorbing environments and precision measurement equipment, allowing engineers to analyze noise across specific frequency bands under different operating conditions.

I walked into the testing room, which looked like the soundproof acoustic testing chambers you might have seen used in several industries, and it was a trippy experience with an unworldly lack of reverb around you.

There, engineers can test a variety of different setups and variable changes to see how they effect a motor’s noise output. That data-driven approach lets the engineers identify exactly where noise is coming from and refine designs over successive generations – the kind of iterative improvement that riders often notice even if they can’t quite explain why a newer motor “just feels better.”

As e-bikes continue to mature, refinement is becoming just as important as raw power. Quiet motors help make rides more pleasant, but they also change how e-bikes are perceived by riders, pedestrians, and regulators alike.

Bafang’s breakdown is a reminder that a lot of sophisticated engineering goes into the parts riders rarely think about – and that the future of better e-bikes may sound more like silence than you’d ever expect!

FTC: We use income earning auto affiliate links. More.

Comments