EV drivetrain and power systems specialist Equipmake has unveiled a new product that strays quite a bit from its electric double-decker buses we’ve covered in the past. Today, the company unveiled the HPM-400 – an advanced high power, short duration electric motor designed for applications in space and the marine segment. This thing is small, but mighty. Check it out.

Equipmake is one of the industry leaders in ultra-high performance electric motors with over two decades of experience specifically developing electric powertrains. Its technology currently ranges from complete EV drive trains like those found in London Buses, to ultra-fast electric power systems.

In recent years, Equipmake has expanded well beyond buses (and Earth) by developing electrified technologies for the aerospace sector. It currently provides advanced electric motors to rockets developed by Gilmour Space Technologies in Australia.

In fact, Equipmake’s latest electric motor unveiled today was originally designed as a high-performance rocket fuel pump for Gilmour in its Eris rocket. Its design allows for multiple applications, however, including as an electric motor for the marine segment and pointed out by Equipmake today.

Equipmake’s new electric motor perfect for marine, space

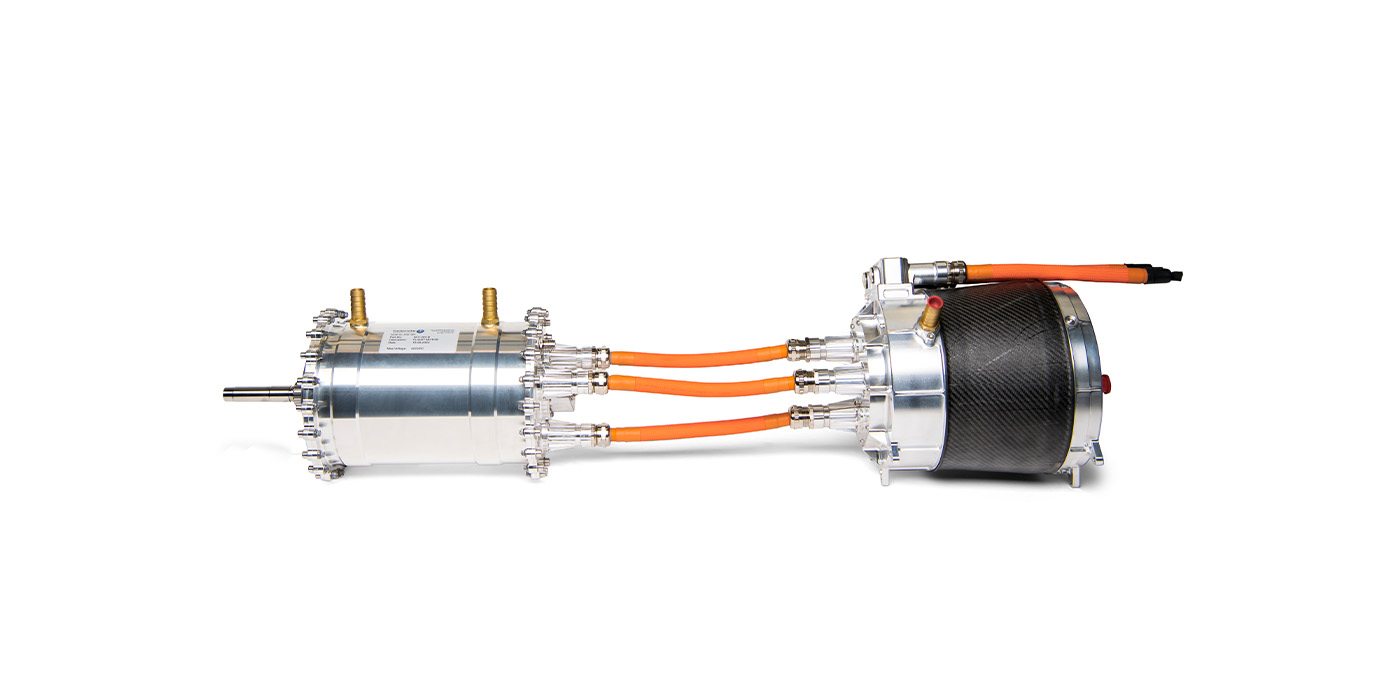

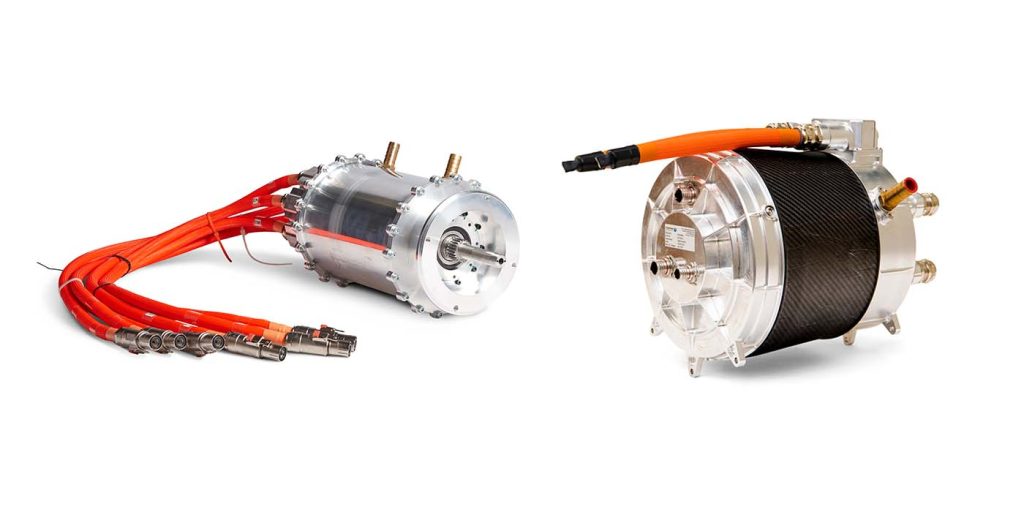

The company officially unveiled the HPM-400 electric motor today, showcasing its max speed of 20,000 rpm, peak power of 400 kW, and maximum torque of 250 Nm – all packed into a mere 40 kg (88 lbs) of mass including its silicon carbide inverter (seen above).

The electric motor debuted during the Future Propulsion Conference in Solihull, UK and although it was originally specificied as a rocket fuel pump, its clever design has plenty more to offer in other sectors like marine and aerospace. Equipmake CEO Ian Foley elaborated:

Because of its original intention for use as a rocket fuel pump, the HPM-400 features several novel innovations over conventional motor/inverters, making it ideal for use in high-performance space, aerospace and marine applications.

Firstly, the complete package is ultra-lightweight and capable of withstanding incredible acceleration. Secondly, when an inverter must operate in a vacuum, it needs to be high voltage, because lots of power is required.

HPM-400 keeps air pressure inside and has been completely redesigned mechanically to withstand the pressure from within when it goes from atmosphere into a vacuum. That has resulted in a super compact cylindrical package – conventional inverters being square – with a carbon fiber shell to keep pressure in and weight down. It all adds up to an advanced high power, low weight motor/inverter that’s at home in space, air or water.

Where this new electric motor might fit in the marine industry or in aerospace technology is yet to be seen, but trust that representatives in those sectors have eyes on the HPM-400 in Solihull and are already brainstorming where its ultra-light, energy dense performance can best be utilized.

FTC: We use income earning auto affiliate links. More.

Comments