Compass Mineral International, a leading supplier of essential minerals like salt and sulfate of potash (used in plant fertilizer), has been pivoting to focus on the “new gold” rush, lithium. The minerals company, which has deals to supply lithium for EV leaders like Ford and LG Energy, is doubling down by using a new extraction technology to obtain the mineral with minimal impact on the environment.

As the largest salt producer in North America and the UK, Compass Minerals plays a vital role in several industries. However, seeing as how the auto industry is transitioning towards electric vehicles, Compass realizes the need for critical battery minerals, such as lithium, will only continue rising.

The company has been in business for over 175 years and generates $1.2 billion in annual revenue, yet, Compass aims to reduce its dependency on weather-dependant minerals to focus on markets with high-growth potential, such as the EV industry.

Furthermore, since the Inflation Reduction Act was passed on August 16, 2022, EVs are expected to see even higher demand with a tax credit of up to $7,500 on new and $4,000 on used EV purchases.

For an electric vehicle to qualify, though, 40% of its battery minerals must be sourced from the US or its free trade partners, which will rise to 80% after 2026.

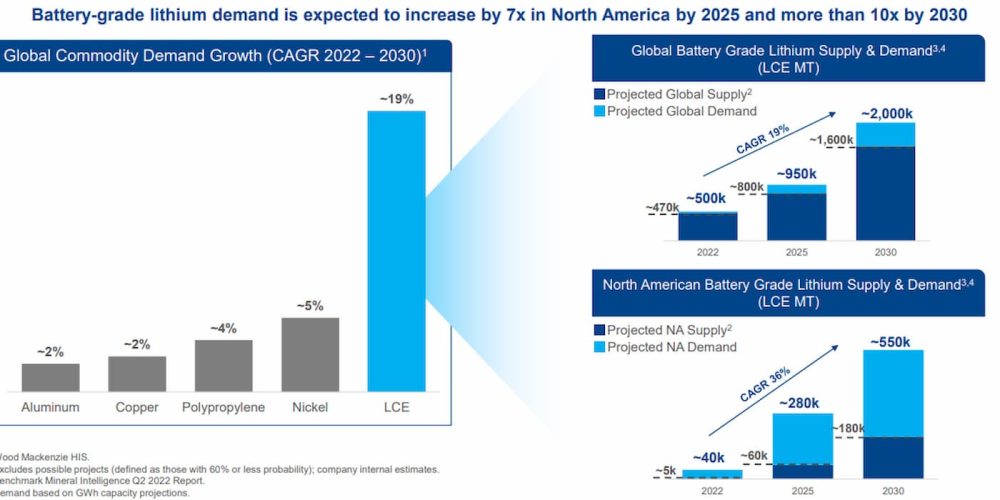

The clause opens a significant opportunity for mineral suppliers like Compass Minerals to step up and fill the growing supply gap. That said, demand for battery-grade lithium in North America is projected to grow by 700% in the next three years, and to over 1,000% by 2030.

New government incentives and skyrocketing prices make lithium mining even more attractive. For this reason, Compass Minerals is advancing its lithium project in Ogden, Utah (close to the Great Salt Lake) with 177,000 leased acres.

Compass Minerals announced another major milestone in the project’s development. The company says it will use EnergySource Minerals’ direct lithium extraction (DLE) technology to remove the mineral with minimal environmental impact. Compass will use the extracted mineral to fulfill supply agreements with EV leaders, including Ford and LG Energy.

Compass Minerals to use lithium extraction method with minimum environmental impact

After three years of “extensive testing,” Compass Minerals went with EnergyMinerals DTC technology due to its superior absorption and minimal environmental impact.

Chris Yandell, Head of Lithium at Compass Minerals, says:

Our selection of ESM is the result of a comprehensive, competitive process, and we are excited to forge ahead on our lithium development with their team as a trusted provider. Our multi-year assessment was focused on matching the right technology with our specific lithium brine resource – and we are confident we’ve done just that with this provider selection.

Compass Minerals says the project has around 2.4 million metric tons of lithium carbonate equivalent (LCE) potential and is fully funded for the next two years. The company also reiterates it remains on track to become a low-cost battery-grade lithium producer by 2025.

Most importantly, because Compass Minerals uses a solar evaporation process, it’s projected to produce significantly fewer greenhouse gas emissions. Rick Axthelm, chief sustainability officer, says:

Minimizing the environmental impact of our lithium extraction and conversion plans has been a key priority of this project since we first began assessing our development options. We will continue to prioritize sustainable operations as we advance toward commercial production.

Electrek’s Take

As more resources (from governments and private businesses) are being dedicated to promoting a sustainable future, better technology and other resources are being developed to lessen the impact of electric vehicles even more than they already are.

Sustainable extraction technology is still in its very early stages. With demand for EVs only expected to continue accelerating in the foreseeable future, lithium will be in high demand.

In particular, new climate initiatives in North America are designed to make sustainable options available to everyone and bring manufacturing back to US soil. For this to happen, sustainable extraction methods will be essential.

FTC: We use income earning auto affiliate links. More.

Comments