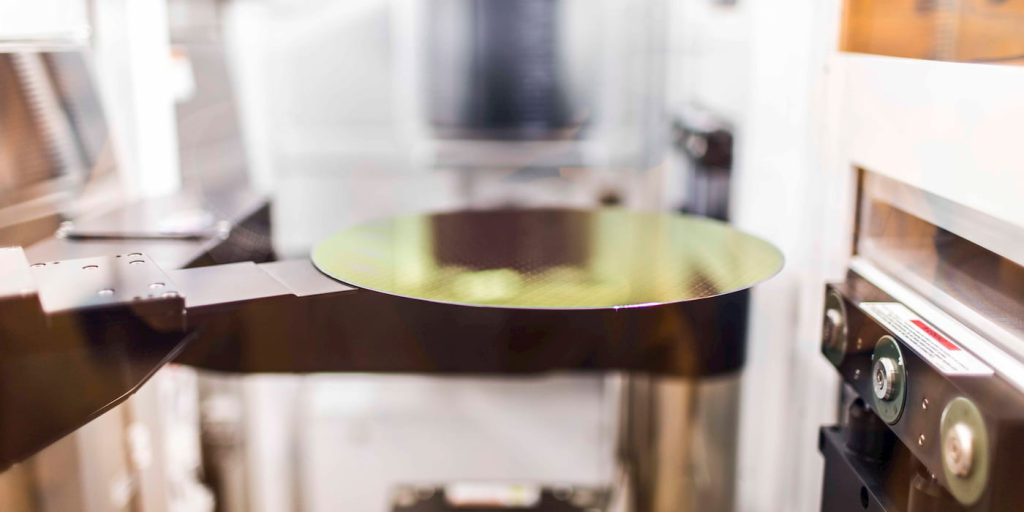

General Motors (GM) announced a new, first-of-its-kind “direct” supply agreement with GlobalFoundries (GFS) for semiconductor wafers.

GM’s new agreement secures EV semiconductor supply

After dealing with semiconductor shortages over the past several years, GM is not taking its chances moving forward.

The company announced today a long-term agreement with leading semiconductor manufacturer GlobalFoundries that gives GM an exclusive dedicated capacity corridor for its chip supply.

GFS will manufacture the wafers directly for key GM suppliers to build higher production volumes and promote better reliability.

Semiconductors are critical in enabling the transition to zero-emission electric vehicles and autonomous driving. EVs require more chips to power advanced capabilities like data acquisition, connectivity, and other tech features.

Dr. Thomas Caulfield, CEO of GFS, explained:

GF will expand its production capabilities exclusively for GM’s supply chain, enabling us to strengthen our partnership with the automotive industry and New York State, while further accelerating automotive innovation with U.S.-based manufacturing for a more resilient supply chain.

Although the semiconductor supply chain has eased over the past year, thanks to investments like the Chips and Science Act providing over $50 billion to establish a reliable US supply chain, demand is still expected to increase significantly over the next decade or so as electric vehicles and autonomous driving technology become the primary means of driving.

For GM to hit its target of 1 million EV sales by 2025, semiconductors will play an integral role. The news comes after a report from Bloomberg claims GM is in deep talks with Vale for a stake in its nickel and copper mining business in addition to the automaker investing $650 million to develop Thacker Pass in Nevada, the largest known supply of lithium in the US.

Electrek’s Take

As the race to make and deliver electric vehicles in the auto industry heats up, automakers with the most reliable and efficient supply chains will likely win out in the end.

That’s why you are seeing GM building out its supply chain to include semiconductors, nickel, copper, lithium, and other critical components needed to manufacture EVs. Expect to see more of this happening over the next few years as automakers look to secure their fate in the new EV era.

FTC: We use income earning auto affiliate links. More.

Comments